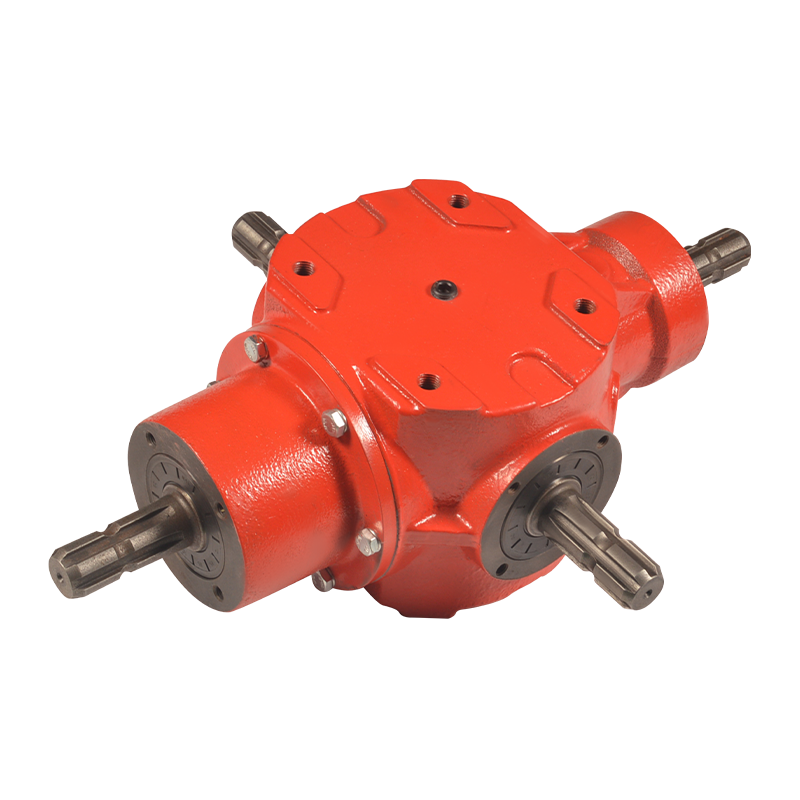

KLF100 Light-weighted crawler tractor gearbox

Cat:Grader Driven Rake Gear Box

This gearbox is used for lightweight crawler Tractors within 80HP. Engine input, power, and torque are transmitted through the gearbox. By driving the...

See DetailsIn the world of mechanical power transmission, gear reducers play a vital role in converting speed and torque to match the requirements of machines and processes. Among the many types of gear reducers, the worm gear reducer holds a distinctive position due to its ability to manage high torque loads in a compact and reliable form. These devices are widely used in industries where heavy loads must be moved efficiently and safely, making them a crucial component in lifting systems, conveyors, presses, and other high torque machinery.

Before understanding the role of worm gear reducers, it is useful to revisit the idea of torque. Torque is a measure of rotational force, calculated as the product of force and the distance from the axis of rotation. In practical terms, torque represents the twisting effect that causes rotation in mechanical systems.

High torque is often required in machines that need to lift heavy weights, move large masses, or apply pressure in processes such as pressing, crushing, or compacting. However, high torque usually comes at the expense of rotational speed. This balance between torque and speed is precisely where gear reducers, particularly worm gear reducers, provide value.

A worm gear reducer consists of two main components: the worm and the worm wheel.

Worm: This is a screw-like shaft that meshes with the worm wheel. It typically has a helical thread designed to engage with the teeth of the wheel.

Worm Wheel: This is a gear shaped like a helical gear but designed to mesh with the worm. The wheel has teeth that fit into the helical groove of the worm shaft.

When the worm rotates, its threads push against the teeth of the worm wheel, causing it to turn. This setup results in a high gear reduction ratio, often in a compact space. The reduction ratio depends on the number of threads on the worm and the number of teeth on the worm wheel.

One of the most important reasons worm gear reducers excel in high torque applications is their ability to achieve significant reduction ratios in a single stage. While other gear types may require multiple stages to achieve the same result, a worm gear reducer can reduce speed dramatically with just one worm and wheel pair. This high reduction directly translates to high torque output.

High torque requirements often mean larger and heavier gearboxes if traditional gear sets are used. Worm gear reducers, however, provide the same output in a compact and space-efficient form. This is advantageous in applications where space is limited but torque demand is high, such as conveyor drives or lifting hoists.

Depending on the lead angle of the worm, worm gear reducers can exhibit a self-locking property. This means the worm can drive the wheel, but the wheel cannot drive the worm. In high torque applications like elevators or hoists, this property prevents reverse motion, enhancing safety without requiring additional braking mechanisms.

Worm gear reducers handle shock loads effectively due to the way force is distributed along the sliding contact of the worm and wheel. This makes them ideal for machinery that experiences sudden changes in load, such as crushers or compactors.

A distinguishing feature of worm gear reducers is the sliding contact between the worm thread and the wheel teeth. Unlike spur gears that rely on rolling contact, worm gears function through sliding engagement. While this creates higher friction and heat compared to other gear systems, it also provides smoother operation and allows for higher torque transmission at lower speeds.

The sliding mechanism contributes to noise reduction as well, which is beneficial in applications requiring quiet operation, such as automated doors, elevators, or stage equipment.

While worm gear reducers are suitable for handling high torque, their performance depends on several factors.

The worm is often made of hardened steel while the worm wheel is typically made of bronze or other softer metals. This combination reduces wear and friction while supporting high torque loads. The choice of materials significantly influences durability in demanding applications.

Friction in worm gears generates heat, especially under high torque conditions. Adequate lubrication is crucial to reduce wear and prevent overheating. Specialized oils with high film strength are often used to ensure a protective layer between the sliding surfaces.

High torque transmission generates heat, which can affect efficiency and longevity. Worm gear reducers often incorporate heat sinks, cooling fins, or external cooling systems in demanding applications to maintain stable operating temperatures.

Worm gear reducers tend to have lower efficiency compared to other gear types, mainly due to sliding friction. However, when high torque is more critical than efficiency, such as in lifting or pressing applications, this trade-off is acceptable. Advances in lubrication technology and precision manufacturing have also improved efficiency levels in modern worm gear designs.

The torque output of a worm gear reducer is directly linked to its reduction ratio. Choosing the right ratio is essential for ensuring that the system delivers sufficient torque without overloading the motor or the gearbox itself.

Worm gear reducers are widely used in cranes, elevators, and hoists where high torque and safety are essential. The self-locking feature ensures that loads remain in place without additional braking systems.

In heavy-duty conveyor systems that transport bulk materials such as coal, ores, or aggregates, worm gear reducers provide the necessary torque to move large masses reliably.

Industrial presses and compactors require significant torque to compress materials. Worm gear reducers allow these machines to operate efficiently, delivering consistent power during heavy-duty cycles.

Some automotive systems, such as steering gears and lifting jacks, incorporate worm gear reducers due to their compact design and torque-handling ability.

Stage lifts and moving platforms use worm gear reducers to handle heavy loads quietly and reliably, benefiting from the low-noise characteristics of worm gear operation.

Worm gear reducers are employed in winches, conveyors, and drilling equipment, where they provide the torque needed to manage heavy loads in demanding environments.

Ability to handle large torque loads in a small form factor

Smooth and quiet operation due to sliding contact

Built-in self-locking feature for added safety

High reduction ratios achievable in a single stage

Durable performance in shock load conditions

Despite their benefits, worm gear reducers have limitations. Their efficiency is generally lower than other types of gear systems due to frictional losses. This also results in higher heat generation, requiring careful attention to lubrication and cooling. Additionally, wear on the worm wheel may occur faster than in rolling contact gears, which means maintenance and replacement are considerations in long-term use.

To maximize performance, users must follow certain practices:

Regular Maintenance: Routine checks for lubrication levels, gear wear, and heat buildup ensure longer life.

Proper Alignment: Misalignment can accelerate wear and reduce torque output.

Quality Lubrication: Using lubricants formulated for worm gears improves efficiency and reduces heat.

Monitoring Load Conditions: Avoiding overloads helps prevent premature failure.

Temperature Control: Installing cooling devices or ensuring proper ventilation prevents overheating.

Advancements in materials science, lubrication technology, and manufacturing precision are improving the performance of worm gear reducers. Coatings that reduce friction, improved bronze alloys, and synthetic lubricants are helping to extend their efficiency and service life. While alternative gear systems may dominate certain sectors, worm gear reducers continue to be irreplaceable in applications where high torque, compactness, and self-locking properties are needed.

Worm gear reducers remain an indispensable solution in industries that demand high torque and reliable power transmission. Their unique design allows them to manage large loads while maintaining safety and compactness. By understanding their operating principles, advantages, and limitations, engineers and operators can make informed choices that maximize the benefits of worm gear reducers in demanding environments.

Through proper selection, maintenance, and application, worm gear reducers continue to provide an effective and efficient means of handling high torque applications across diverse fields, ensuring machines operate smoothly, safely, and with lasting durability.