In the world of modern agriculture, productivity is measured in acres per day and yield per acre. Between the raw power of the tractor and the soil-shattering work of the implement lies a component that is often overlooked but is absolutely critical to success: the heavy-duty tillage gearbox. This isn’t just a simple metal box; it’s the heart of the power transmission system, a precision-engineered hub that dictates the efficiency, reliability, and ultimately, the profitability of your primary tillage operations.

The Unseen Workhorse: Function and First Principles

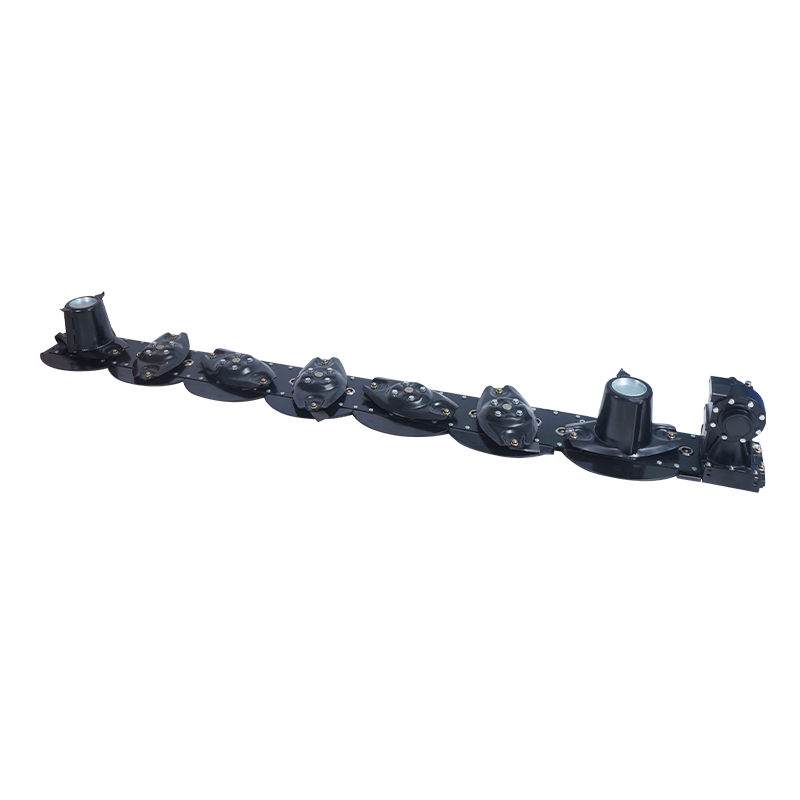

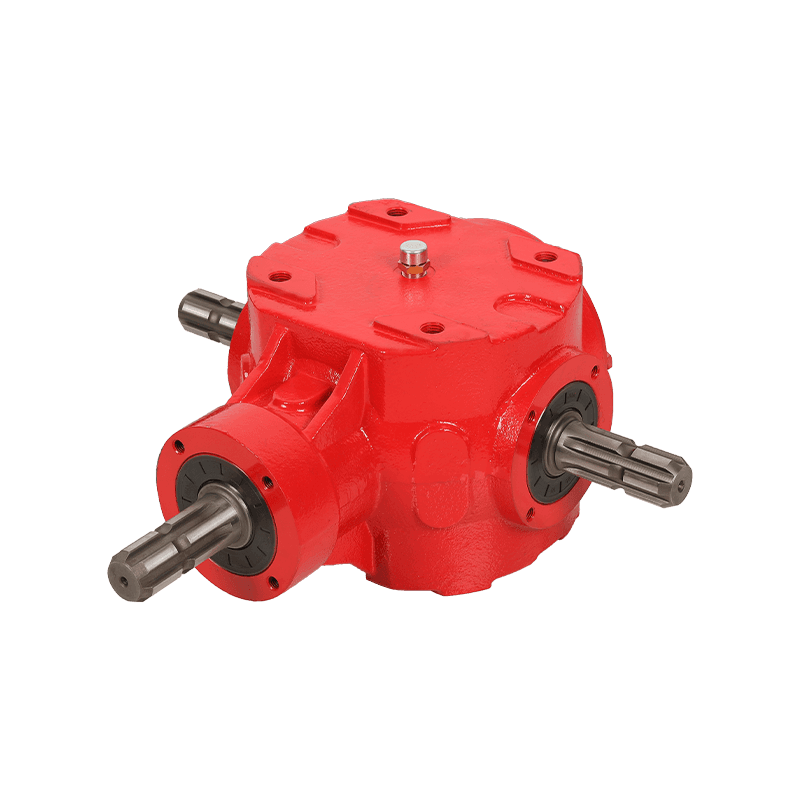

Before appreciating its heavy-duty nature, one must understand its fundamental role. A tillage gearbox is a power transmission component specifically designed for agricultural rotary tillers, power harrows, bedders, and other intensive tillage implements. Its primary functions are:

Power Transmission: It takes the mechanical power from the tractor’s Power Take-Off (PTO) and transfers it to the implement’s driveline.

Speed Reduction: PTOs typically operate at 540 or 1000 RPM. Most tillage tools, like the flails on a rotary tiller, require a specific, often slower, operational speed to achieve the desired soil fracturing and mixing action. The internal gearing of the gearbox provides this crucial speed reduction.

Torque Multiplication: As the gearbox reduces speed, it inversely increases torque. This is the fundamental principle that provides the immense rotational force needed to drive tines or blades through tough, compacted soil, even in rocky conditions.

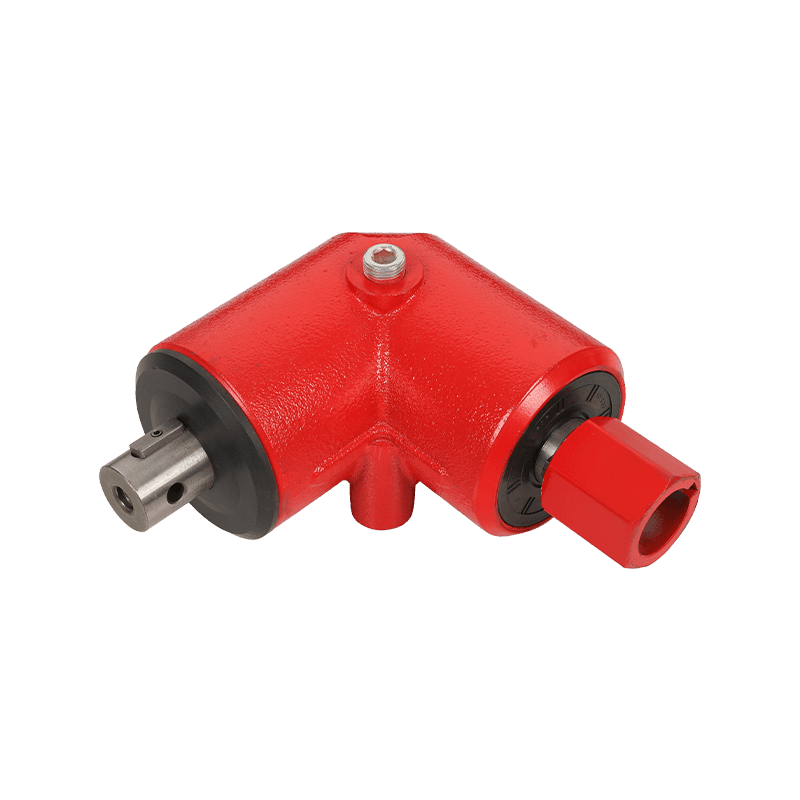

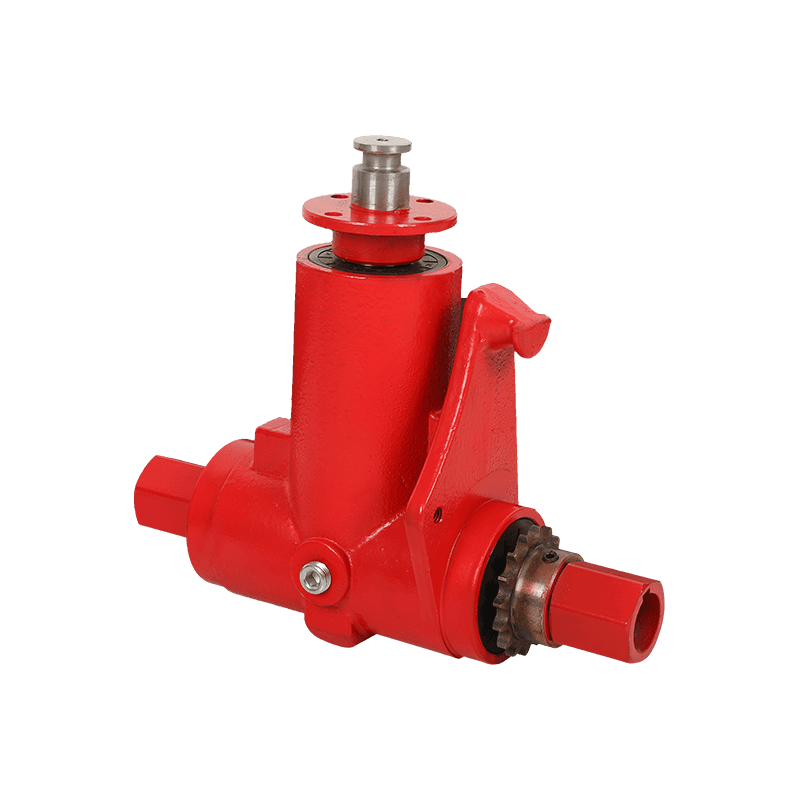

Direction Change: Many gearboxes are designed with a 90-degree configuration, turning the horizontal rotational power from the PTO shaft into a vertical (or near-vertical) rotation to drive the implement’s rotor.

A failure in this component doesn’t just mean a delay; it means a complete stoppage of work, often during the critical, time-sensitive windows of planting season.

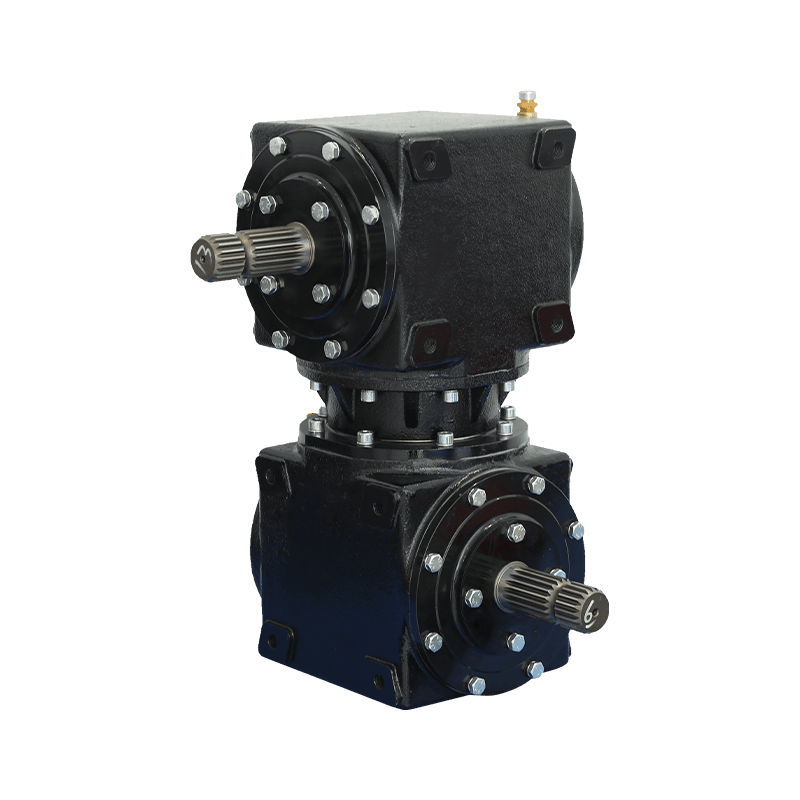

What Makes it “Heavy-Duty”? Key Engineering Features

The term “heavy-duty” is more than a marketing slogan. It refers to a suite of design and material choices engineered to handle peak loads, shock loads, and the abrasive, high-vibration environment of tillage.

1. Robust Housing Design and Materials:

The gearbox housing is its first line of defense. Standard gearboxes may use lighter cast iron or even fabricated steel. Heavy-duty agricultural gearboxes are almost exclusively constructed from high-grade, nodular cast iron (e.g., ASTM A536 65-45-12). This material offers an exceptional strength-to-weight ratio, high impact resistance, and excellent damping properties to absorb vibrations that would otherwise fatigue and destroy bearings and gears.

2. High-Carbon and Alloy Steel Gearing:

The gears are the soul of the unit. Light-duty gears might be machined from lower-grade steels. Heavy-duty versions utilize case-hardened spiral bevel gears. The spiral design allows for more teeth to be in contact at any given time compared to straight bevel gears, resulting in smoother, quieter operation and a dramatically higher load-carrying capacity. The case-hardening process creates an incredibly hard, wear-resistant outer surface while maintaining a tough, ductile core that can withstand shock loads—like hitting a buried rock—without shattering.

3. Superior Bearing and Seal Technology:

Bearings support the massive radial and axial loads generated during tillage. Heavy-duty gearboxes employ oversized, high-quality tapered roller bearings. These are precisely pre-loaded during assembly to eliminate internal play, ensuring perfect gear alignment under load and maximizing bearing life.

Seals are equally critical. They must keep the high-performance lubricant in and keep out the most destructive contaminant: soil. Labyrinth seals and double-lip radial shaft seals, often made from advanced nitrile or viton compounds, are standard on high-end gearboxes. Some feature optional ceramic face seals for the most extreme, abrasive conditions, offering near-total protection against dust ingress.

4. Efficient Lubrication and Thermal Management:

The intense friction between gears and bearings generates significant heat. A heavy-duty gearbox is designed for optimal lubrication. This includes precisely calculated oil volumes, strategically placed oil channels (oil slingers) to ensure all components are bathed in lubricant, and large cooling fins on the housing to dissipate heat into the air. Using the correct extreme pressure (EP) lubricant is non-negotiable, as it maintains its protective viscosity and film strength under high pressure and temperature.

5. Standardized Mounting and PTO Connections:

To ensure compatibility across a wide range of implements, quality gearboxes adhere to established agricultural gearbox standards, such as those set by the Agricultural Industry Manufacturers (AEM). This includes standardized bolt patterns, shaft diameters, and PTO input dimensions. This interchangeability is a huge benefit for farmers and equipment manufacturers alike.

The Critical Link: Matching the Gearbox to the Implement and Tractor

Selecting the right gearbox is not a one-size-fits-all process. An undersized gearbox will inevitably fail, while an oversized one adds unnecessary cost and weight. Key selection criteria include:

Horsepower Requirements: The gearbox must be rated for the maximum continuous horsepower of your tractor, plus a safety factor for shock loads.

Gear Ratio: This determines the output speed of the implement. A rotary tiller gearbox will have a different ratio than a power harrow gearbox. Using the wrong ratio will result in poor performance and potential damage.

Input Speed: Ensure the gearbox is rated for either 540 RPM or 1000 RPM to match your tractor’s PTO setting.

Physical Size and Mounting: The gearbox must physically fit the implement frame and align correctly with the driveline.

Direction of Rotation: Verify that the input and output rotation directions meet the requirements of your specific implement.

Consulting your implement’s manual or working with a knowledgeable distributor is essential for correct tillage gearbox selection.

Proactive Maintenance: Maximizing Uptime and Longevity

Even the toughest gearbox will fail without proper care. A simple, consistent maintenance routine is the best insurance policy against costly downtime and repairs.

1. Lubrication is Everything:

Use the Right Oil: Always use the manufacturer-recommended lubricant, typically a high-quality EP GL-4 or GL-5 gear oil. The wrong oil can lead to rapid wear and pitting.

Check Levels Religiously: Before each use, check the oil level with the implement level. The oil should be at the bottom of the fill plug hole. Modern agricultural gearboxes often have sight glasses for easier checking.

Change Oil Periodically: Contaminants like metal wear particles and moisture accumulate over time. Follow the manufacturer’s change intervals, typically after the first 50-100 hours of break-in and then every 500-1,000 hours thereafter. In severe conditions, change it more frequently.

2. Daily Visual and Auditory Inspection:

Look for Leaks: Check for oil seepage around seals and gaskets. A leak means contaminants are getting in and lubricant is getting out.

Listen for Sounds: A change in sound is a primary indicator of trouble. A healthy gearbox has a consistent, meshing hum. Grinding, whining, or knocking noises signal immediate problems like bearing failure or gear damage.

Feel for Heat: After operation, carefully touch the gearbox housing. It should be warm, not hot. Excessive heat indicates overloading, low oil, or the wrong oil.

3. Driveline and Implement Alignment:

A poorly aligned PTO driveline places enormous side-load stress on the gearbox’s input shaft and bearings, leading to premature seal failure and bearing wear. Ensure your driveline is the correct length and that the implement hitch is adjusted to maintain a straight line between the tractor PTO and the gearbox input shaft during operation.

Signs of Impending Failure and Troubleshooting

Catching a problem early can turn a major rebuild into a simple seal replacement.

Oil Leakage: The most common sign. Usually indicates a failed output or input shaft seal.

Unusual Noise: Grinding often points to bearing failure or gear wear. A rhythmic knock could mean a chipped gear tooth.

Excessive Vibration: This can be caused by worn bearings, damaged gears, or a failing universal joint on the driveline.

Oil Milky or Foamy: This indicates water contamination, which destroys the lubricant’s properties and leads to rapid internal corrosion.

For many farmers and repair shops, opting for a replacement tillage gearbox is often more cost-effective and faster than a complex rebuild, especially when downtime during a short planting window is considered.

The Future of Tillage Power Transmission

Engineering never stands still. The future of heavy-duty tillage gearboxes involves even greater integration of technology. This includes:

Integrated Sensors: Sensors for monitoring oil temperature, oil level, and vibration in real-time, feeding data to the tractor’s cabin to provide early warning of potential issues.

Advanced Materials: Further development in composite seals and surface treatments for gears to push the boundaries of efficiency and durability.

Precision Lubrication Systems: Automated systems that ensure perfect lubrication levels are maintained continuously.

Conclusion: An Investment in Reliability

The heavy-duty tillage gearbox is a masterpiece of focused engineering. It is not a commodity but a critical investment in the reliability and productivity of your farming operation. By understanding the principles behind its strength, selecting the correct unit for your application, and adhering to a disciplined maintenance regimen, you are not just protecting a metal box—you are ensuring that when the season demands it, your equipment will perform with the relentless strength it was engineered for. In the relentless environment of primary tillage, this reliability is the ultimate currency.

English

English 中文简体

中文简体 عربى

عربى русский

русский Español

Español