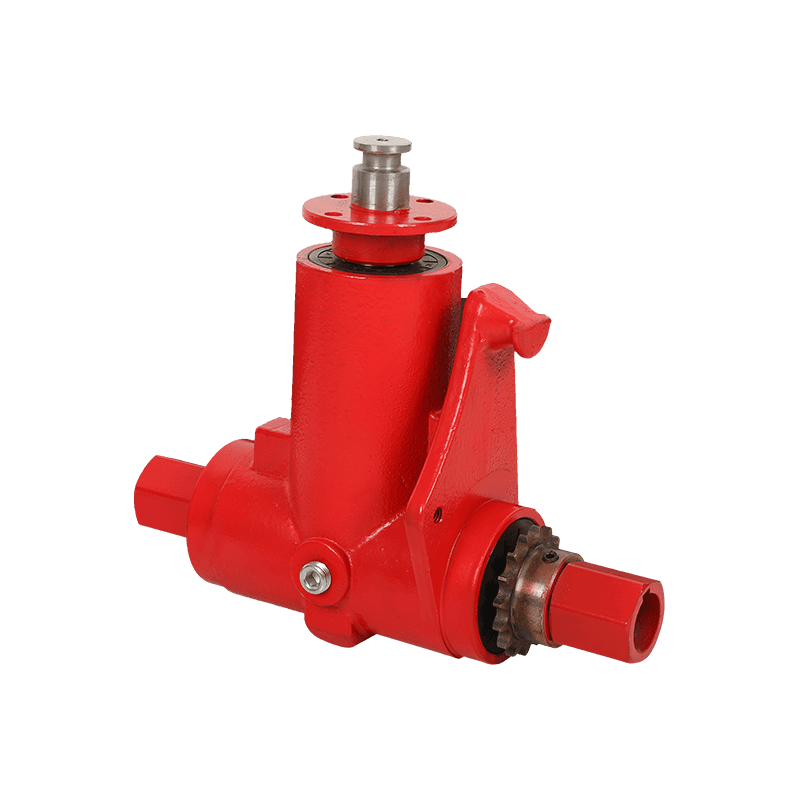

KLF190-R3 Seeder machine auger gearbox Reducer

Cat:Fertilizer Seeder Type Gearbox

This product can be used in conjunction with other products to transmit power through the drive shaft. Linked auger gearboxes, auger gearboxes can be ...

See DetailsFertilizer spreaders are essential tools in modern agriculture, designed to distribute nutrients evenly across fields. A key component in these machines is the gearbox, which ensures that the spreading mechanism operates efficiently and consistently. Understanding how a fertilizer spreader gearbox functions can help farmers maintain uniform distribution, reduce wastage, and improve crop yield.

At its core, a fertilizer spreader gearbox transfers power from the tractor or motor to the spreading mechanism. The gearbox controls the rotation speed of the spreader discs or rollers, which directly affects how fertilizer is thrown across the field.

Without a properly functioning gearbox, the spreader may deliver uneven application rates, leading to fertilizer hotspots or bare patches, both of which can negatively impact crop growth.

The gear ratio in a gearbox determines how fast the output shaft rotates compared to the input. In fertilizer spreaders, this ratio is carefully calculated to match the field speed with the desired application rate.

By adjusting the gearbox ratio or selecting gearboxes with suitable ratios, operators can achieve precise control over the distribution pattern.

Most fertilizer spreaders use simple spur or helical gear systems, while larger or high-capacity models may include planetary gearboxes.

The choice of gearbox influences not only efficiency but also the uniformity of fertilizer distribution.

A gearbox must transmit torque efficiently to ensure that the spreading discs rotate at a consistent speed. Uneven torque can cause variable disc rotation, leading to uneven fertilizer spread.

Modern spreader gearboxes are designed to handle variable loads, such as uneven field terrain or changes in fertilizer type, ensuring consistent operation. Some gearboxes include overload protection mechanisms to prevent damage when encountering blockages or heavy material.

Even the best-designed gearbox will fail to provide uniform distribution if not properly maintained. Key maintenance practices include:

Routine maintenance reduces downtime and keeps the fertilizer spreader delivering nutrients evenly across the field.

A well-functioning gearbox ensures that fertilizer is applied at a consistent rate and uniform pattern, reducing wastage and improving crop growth. Uneven distribution can lead to over-fertilized areas, increasing runoff risk, or under-fertilized zones, limiting plant development.

By providing reliable control over disc speed and torque, the gearbox plays a central role in sustainable and efficient fertilizer application.

When selecting or operating a fertilizer spreader gearbox, farmers should consider:

These factors ensure that the gearbox contributes effectively to uniform fertilizer distribution.

The gearbox in a fertilizer spreader is much more than a mechanical link—it is a critical component that ensures consistent disc rotation, appropriate torque, and precise control over the application rate. Through proper selection, calibration, and maintenance, a fertilizer spreader gearbox can significantly improve the uniformity of nutrient distribution, enhancing crop yield and reducing resource wastage.

Understanding the mechanics and role of the gearbox allows farmers to make informed decisions, ensuring that every pass across the field delivers fertilizer efficiently and evenly.