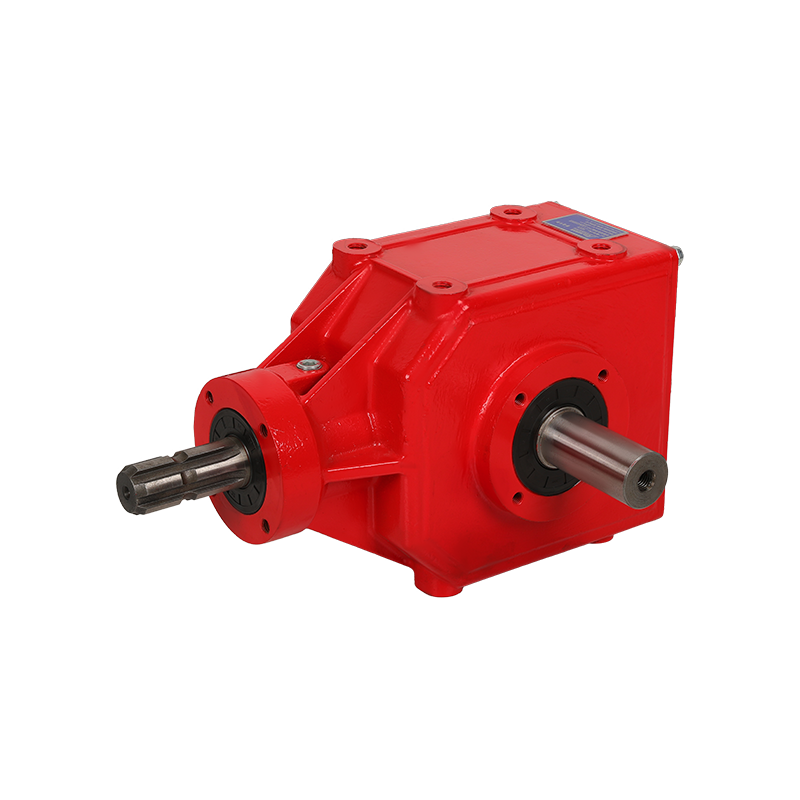

KLF-DXB220 Power driven rake transmission Gearbox

Cat:Grader Driven Rake Gear Box

This product is used in the power-driven rake main transmission gearbox. It is derived from European and American design concepts. The main transmissi...

See DetailsIn the world of machinery and mechanical automation, there’s a silent workhorse that rarely gets the spotlight but is fundamental to motion control in countless applications: the universal gearbox. Whether you’re an engineer designing a new system, a maintenance technician troubleshooting a failure, or a hobbyist building a complex project, understanding gearboxes is crucial. This article delves into what a universal gearbox is, how it works, the common types available, and the critical factors to consider when selecting one for your specific needs.

At its core, a gearbox is a mechanical device that uses a set of gears to transmit power from a source, like an electric motor or engine, to an output device. It serves three primary functions:

The term “universal” in this context often refers to a gearbox designed with a degree of adaptability. It typically features standardized mounting interfaces (like flanges or foot mounts) and input/output shaft configurations, allowing it to be easily connected to a variety of standard motors and driven equipment. This versatility makes it a go-to component across industries.

While “universal” describes adaptability, most gearboxes fall into specific categories based on their internal gear arrangement. Knowing these types is the first step in making an informed selection.

Helical Gearbox: Characterized by gears that are cut at an angle, helical gearboxes operate more smoothly and quietly than other types. The teeth engage gradually, leading to less vibration and higher load-bearing capacity. They are highly efficient and are a popular choice for a wide range of industrial applications, including conveyors, extruders, and crushers, where noise is a consideration.

Worm Gearbox: This type uses a threaded screw (the worm) to mesh with a gear (the worm wheel). Its most significant advantage is its compact design and its ability to provide very high reduction ratios in a single stage. A key feature is its inherent self-locking capability, which prevents the output shaft from back-driving the input, a critical safety feature for hoists and conveyor inclines. They are generally less efficient than helical units but are invaluable where space is limited.

Bevel Gearbox: Designed to change the direction of power transmission, bevel gearboxes employ cone-shaped gears with angled teeth. The most common arrangement allows for a 90-degree direction change, but other angles are possible. They are essential in applications like power tools, automotive differentials, and printing presses.

Planetary Gearbox (Epicyclic): Named for its sun-and-planet-like gear system, this design is known for its exceptional durability, high torque density, and compact size relative to its power output. The load is distributed across multiple planet gears, resulting in high torsional stiffness and efficiency. They are often the preferred choice for high-precision applications like robotics, aerospace actuators, and CNC machinery.

Choosing the correct gearbox is not about finding the “best” one overall, but the best one for your specific application. Here are the essential parameters to evaluate:

Load Characteristics: This is paramount. You must define the nature of the load the gearbox will drive.

Required Torque and Power: Calculate the output torque (in Nm or lb-ft) needed for your application. This, along with the input speed (RPM), will determine the necessary power rating of the gearbox. Always incorporate a service factor—a safety margin—into your calculations to account for unexpected overloads and ensure longevity.

Reduction Ratio: This is the ratio of the input speed to the output speed. For example, a 10:1 ratio means the output shaft rotates once for every ten rotations of the input shaft. Selecting the correct ratio is critical for achieving the desired output speed and torque.

Duty Cycle: How often will the equipment run? A gearbox for a system that runs 24/7 will need to be more heavy-duty than one used for a few minutes per hour. Continuous duty applications require robust construction and effective thermal management to dissipate heat.

Mounting Configuration and Size: The physical constraints of your machine are critical. Consider the gearbox’s footprint, the orientation of the input and output shafts, and the type of mounting (foot-mounted, flange-mounted, or shaft-mounted) to ensure it integrates seamlessly with your motor and driven equipment.

Environmental Conditions: Will the gearbox operate in a clean, climate-controlled environment or a harsh one? Exposure to extreme temperatures, moisture, dust, chemicals, or corrosive elements will dictate the need for specific seals, special coatings, or manufactured materials like stainless steel.

Even the best gearbox will fail prematurely if installed or maintained improperly.

A universal gearbox is far more than a simple metal box with gears; it is a precision-engineered component that is fundamental to motion control. By understanding its functions, the different types available, and the critical selection criteria, you can make an informed decision that ensures reliability, efficiency, and longevity for your machinery. Taking the time to properly specify, install, and maintain this vital component will pay dividends in performance and operational cost for years to come.