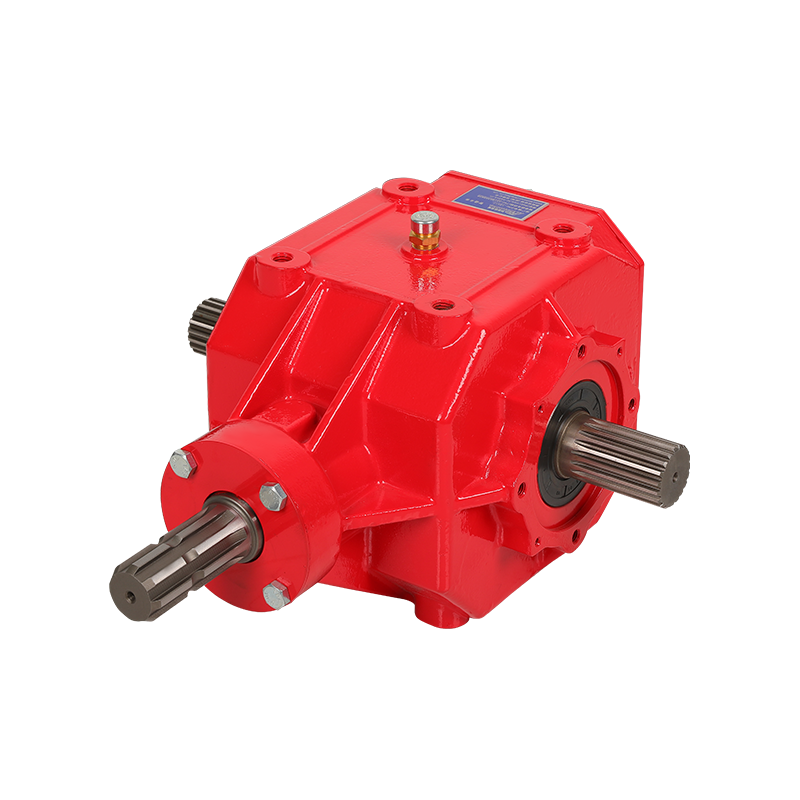

KLF-SF10-R Amazone fertiliser spreader gearbox

Cat:Fertilizer Seeder Type Gearbox

The gearbox design originates from Germany's AMAZONE fertilizer spreader gearbox. Imported original design, one equipped with 3 gearboxes. To achieve ...

See DetailsIn the realm of industrial machinery, precision and safety are paramount. The grader driven rake gearbox stands as a paragon of engineering ingenuity, seamlessly blending functionality with fail-safe mechanisms. This sophisticated system is not merely a mechanical marvel but also a bastion of operational security.

At its core, the design integrates a series of redundant safeguards to mitigate risks during operation. For instance, an advanced torque-limiting mechanism ensures that excessive rotational forces do not compromise structural integrity. Such over-engineering prevents catastrophic failures, even under unpredictable load conditions.

Furthermore, thermal regulation plays a pivotal role in maintaining equilibrium within the gearbox. Embedded heat-dissipating channels circulate coolant fluid, preemptively averting overheating scenarios. These micro-channels act as a thermodynamic shield, preserving the longevity of internal components while enhancing performance consistency.

The inclusion of fail-safe clutch systems elevates the design’s resilience. Should unforeseen obstructions arise, these clutches disengage instantaneously, halting potential damage propagation. It’s akin to having an invisible guardian, ever-vigilant and ready to intervene when anomalies threaten operational harmony.

Material selection further underscores the commitment to safety. High-grade alloys, resistant to both corrosion and fatigue, form the backbone of this gearbox architecture. Such materials are chosen not only for their durability but also for their ability to withstand dynamic stress without deformation or degradation.

Another noteworthy feature is the incorporation of real-time diagnostic sensors. These unobtrusive yet highly sensitive devices monitor vibration patterns, temperature fluctuations, and alignment discrepancies. By providing actionable insights into the health of the system, they empower operators to address issues proactively rather than reactively.

Moreover, ergonomic considerations extend beyond mere functionality. Access panels are strategically placed to facilitate swift inspections and maintenance routines. This thoughtful placement minimizes downtime, ensuring that any required interventions can be executed with minimal disruption to workflow efficiency.

To augment user confidence, the design adheres rigorously to international safety standards. Certifications from accredited bodies validate its compliance with stringent regulations, offering peace of mind to stakeholders across industries.

In essence, the grader driven rake gear box transcends conventional expectations by embedding multiple layers of protection into its blueprint. From torque control to thermal management, every facet reflects meticulous attention to detail. This harmonious fusion of innovation and safeguarding measures positions it as a cornerstone of modern industrial applications.

When it comes to machinery that operates on gradients—where variables abound and unpredictability reigns—the importance of such robust safety features cannot be overstated. After all, reliability isn’t just a feature; it’s a necessity.