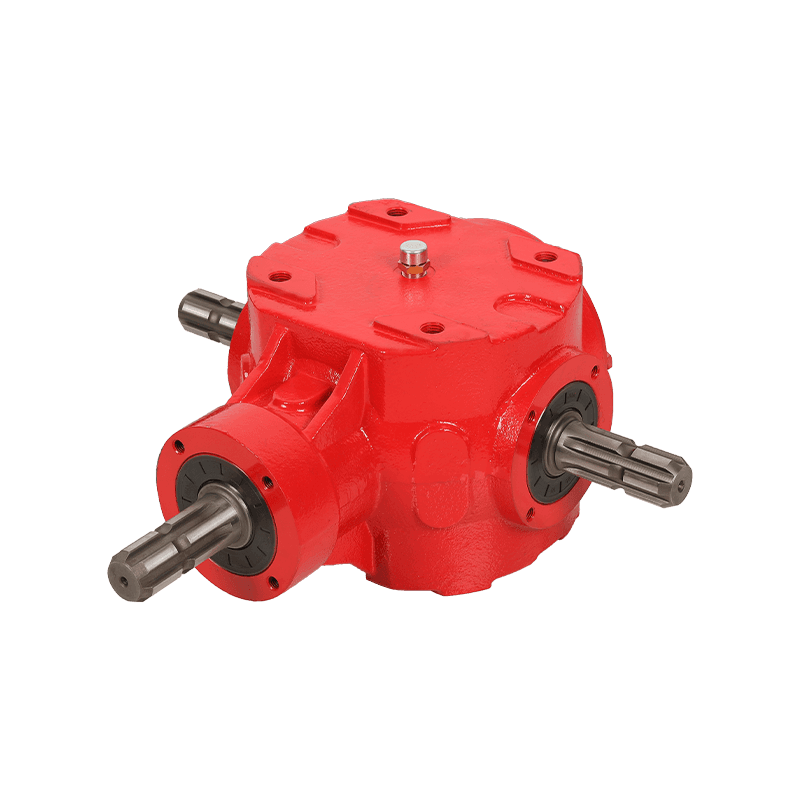

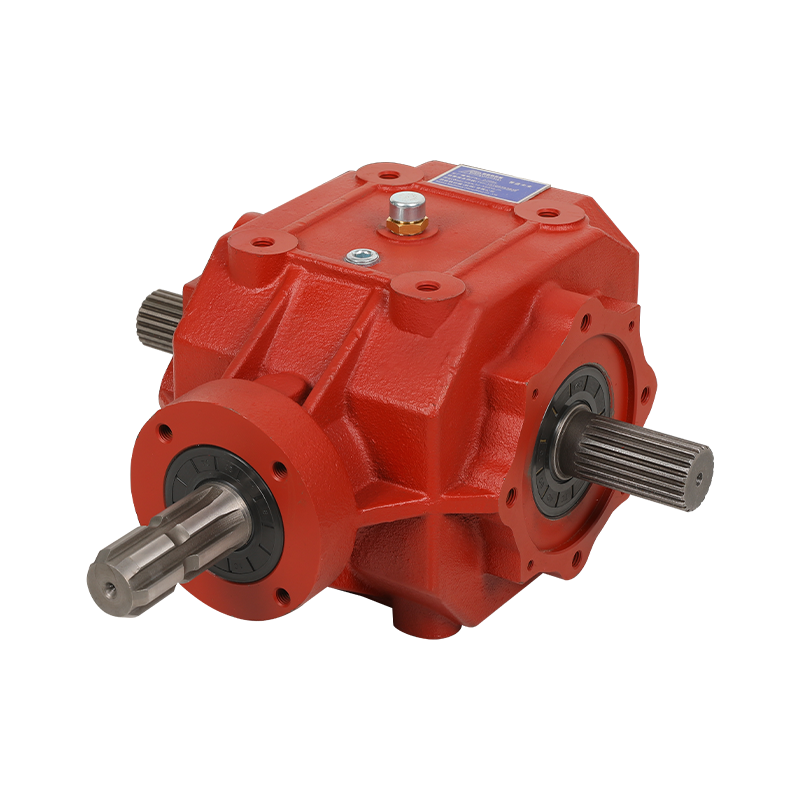

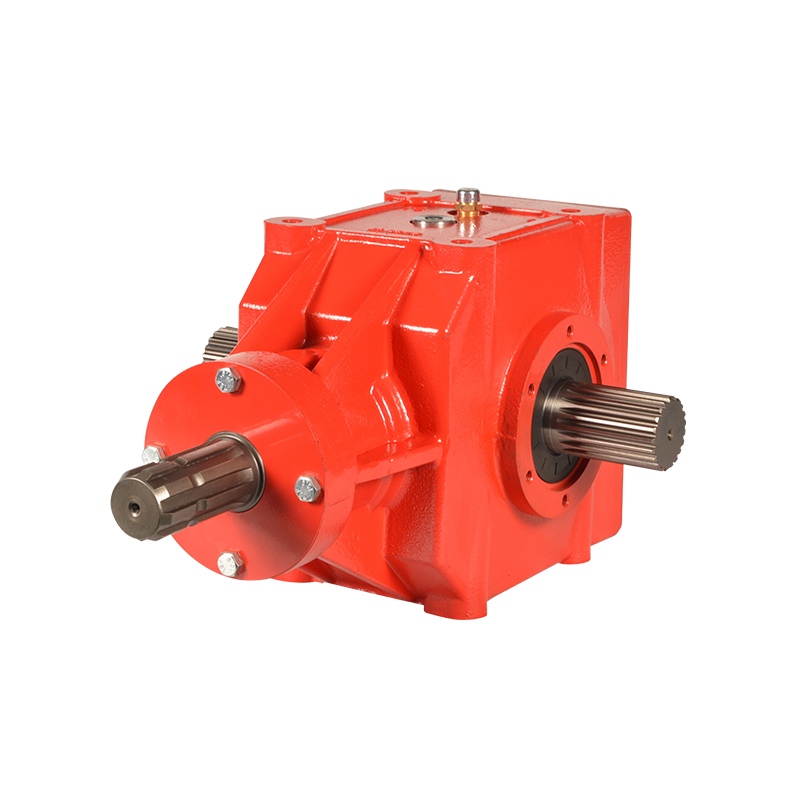

In the realm of mechanical engineering, the universal gearbox stands as a paragon of ingenuity. Its ability to mitigate noise and vibration is nothing short of remarkable. This intricate machinery employs an array of sophisticated mechanisms, each designed to ensure smooth operation and unparalleled performance.

At its core, the universal gearbox leverages helical gearing—a design that minimizes acoustic emissions. Unlike spur gears, which can produce a cacophony of sound due to abrupt tooth engagement, helical gears feature angled teeth that mesh gradually. This gradual interaction not only reduces decibels but also imparts a fluidity to rotational motion, diminishing jarring vibrations.

Furthermore, precision-engineered bearings play a pivotal role in this symphony of silence. These components act as sentinels, absorbing extraneous oscillations before they propagate through the system. By employing advanced materials such as ceramic composites or hybrid polymers, these bearings exhibit exceptional damping properties. Such innovations transform chaotic energy into imperceptible warmth, leaving behind a whisper-quiet mechanism.

The inclusion of elastomeric couplings represents another stroke of brilliance. These flexible connectors serve as mediators between moving parts, isolating them from one another's kinetic disturbances. Their viscoelastic nature absorbs shocks and attenuates harmonics, effectively neutralizing disruptive frequencies. In essence, they function as guardians of tranquility within the gearbox architecture.

Lubrication, too, emerges as a cornerstone of noise reduction. High-performance synthetic oils coat gear surfaces with microscopic precision, forming a near-frictionless barrier. This lubricious film prevents metal-on-metal contact, eradicating the screeches and groans associated with wear. Moreover, it dampens vibrational resonance by introducing viscous resistance into the equation, further refining operational harmony.

Dynamic balancing is yet another technique wielded by engineers to quell unwanted commotion. Each rotating element undergoes meticulous calibration to eliminate eccentricities. Even the slightest imbalance can generate centrifugal forces capable of inducing rattles and hums. Through rigorous testing and adjustment, these elements achieve equilibrium, ensuring seamless rotation devoid of discordant reverberations.

Lastly, enclosure design cannot be overlooked in this discourse on serenity. The housing itself often incorporates sound-absorbing materials, such as laminated composites or perforated panels lined with fibrous insulation. These structural enhancements trap airborne noise, preventing it from escaping into the surrounding environment. Additionally, strategic ribbing and gusseting reinforce the casing, suppressing panel resonance and enhancing overall stability.

The universal gearbox is a marvel of modern engineering, embodying principles of acoustics, material science, and dynamics. Its multifaceted approach to reducing noise and vibration underscores a commitment to excellence. From helical gears and elastomeric couplings to advanced lubricants and balanced rotors, every component plays a vital role in crafting a machine that operates with grace and efficiency. For industries seeking reliability coupled with auditory peace, the universal gearbox remains an unrivaled choice.

English

English 中文简体

中文简体 عربى

عربى русский

русский Español

Español