Gearboxes are essential components in various mechanical systems, providing torque conversion, speed reduction, and power transmission. Among them, the universal gearbox stands out due to its adaptability across multiple industries. This article explores the types, applications, benefits, and selection criteria for universal gearboxes, providing valuable insights for engineers, technicians, and industry professionals.

A universal gearbox is a versatile transmission system designed to accommodate different mechanical requirements. Unlike specialized gearboxes, it can be adapted for various applications, making it a cost-effective solution for many industries.

Key Features of Universal Gearboxes

- High Efficiency – Minimizes energy loss during power transmission.

- Durability – Built to withstand heavy loads and harsh conditions.

- Modularity – Can be customized with different gear ratios and mounting options.

- Low Maintenance – Engineered for long service life with minimal upkeep.

Types of Universal Gearboxes

Universal gearboxes come in different configurations, each suited for specific applications. Below is a comparison of the most common types:

| Type |

Description |

Best For |

| Helical Gearbox |

Uses helical gears for smooth, quiet operation. |

High-speed, high-torque applications. |

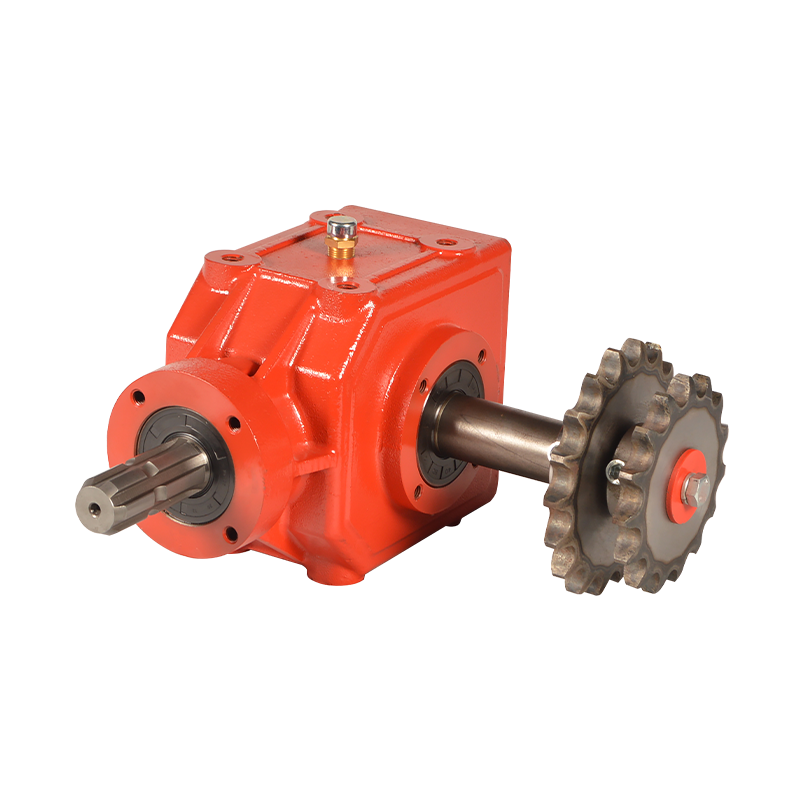

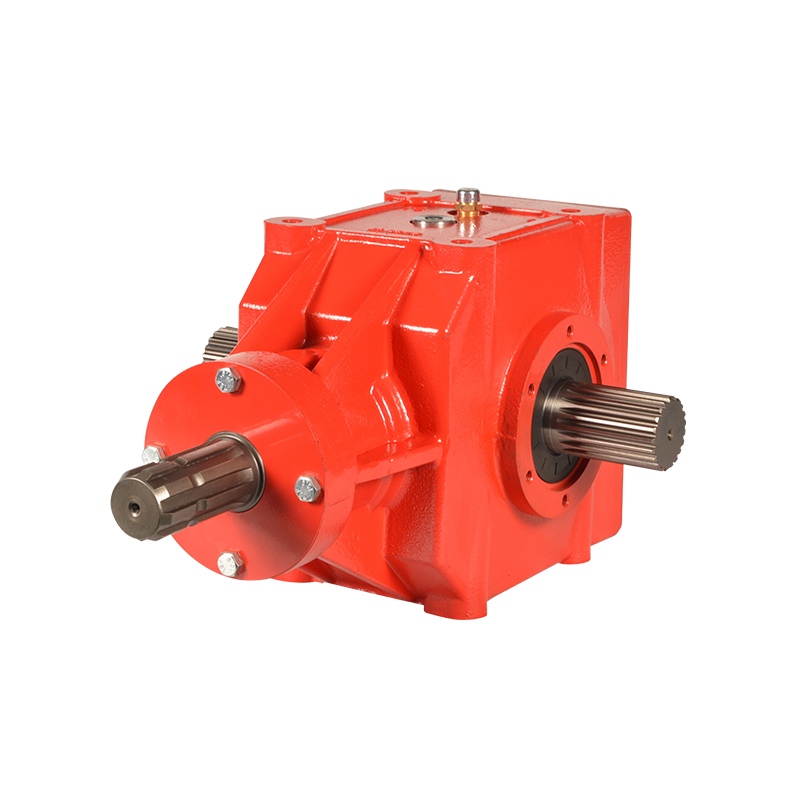

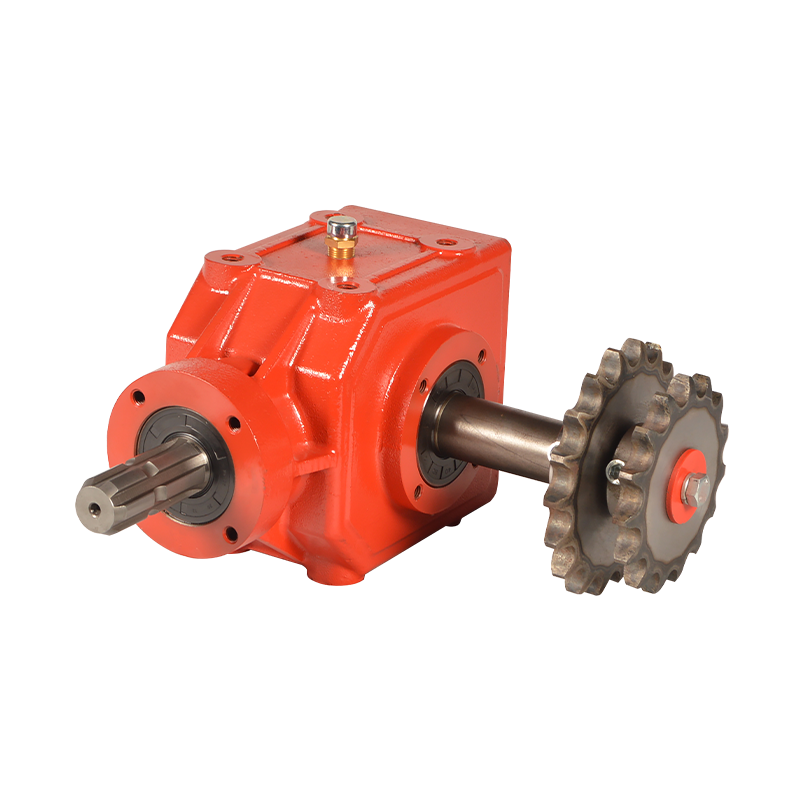

| Bevel Gearbox |

Features bevel gears for right-angle power transmission. |

Conveyors, printing machines. |

| Worm Gearbox |

Uses a worm and wheel mechanism for high reduction ratios. |

Heavy-duty lifting equipment. |

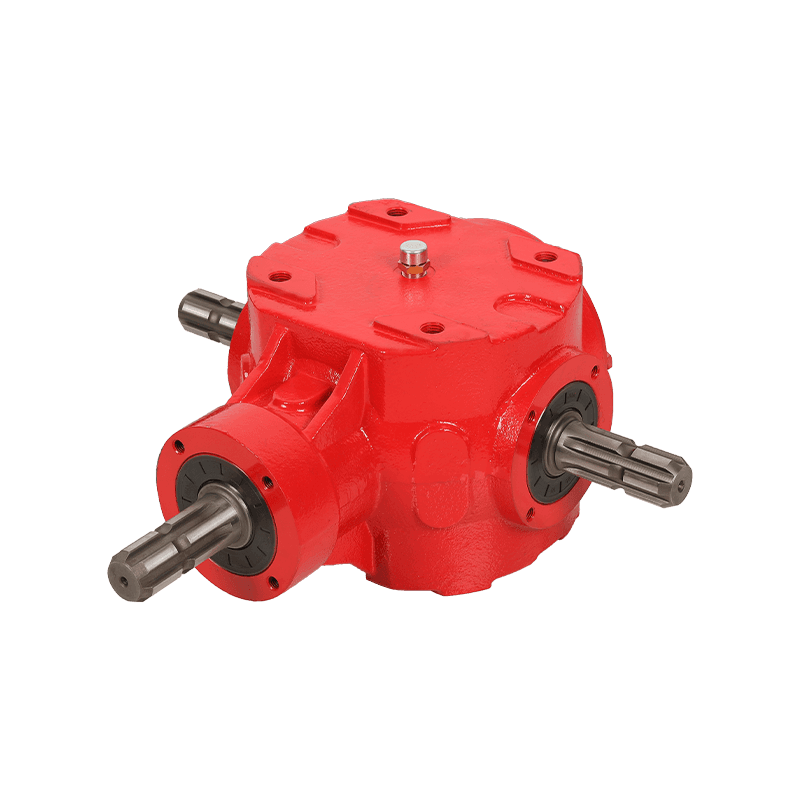

| Planetary Gearbox |

Multiple gears rotating around a central gear for high torque density. |

Robotics, automation systems. |

Applications of Universal Gearboxes

Universal gearboxes are widely used across industries due to their flexibility. Some common applications include:

1. Industrial Machinery

- Conveyor systems

- Mixers and agitators

- Packaging machines

2. Automotive Sector

- Power transmission in vehicles

- Differential systems

3. Renewable Energy

- Wind turbine pitch control

- Solar tracking systems

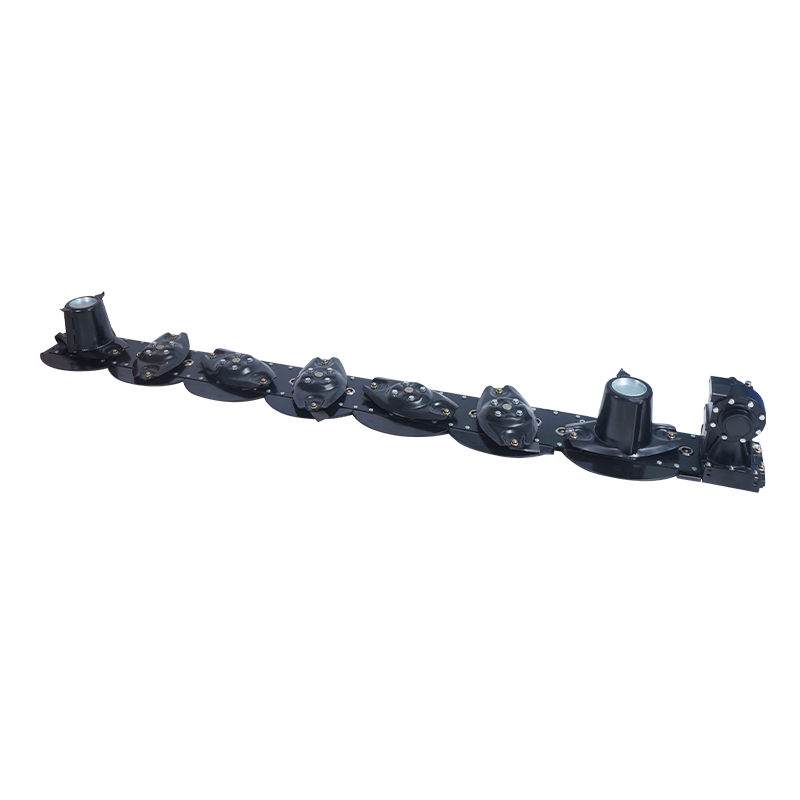

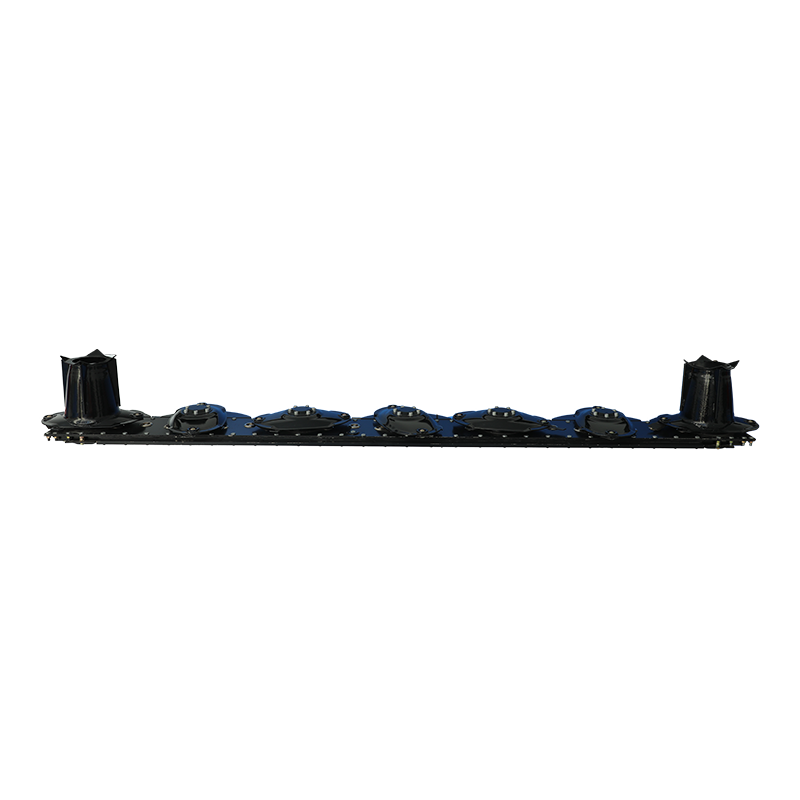

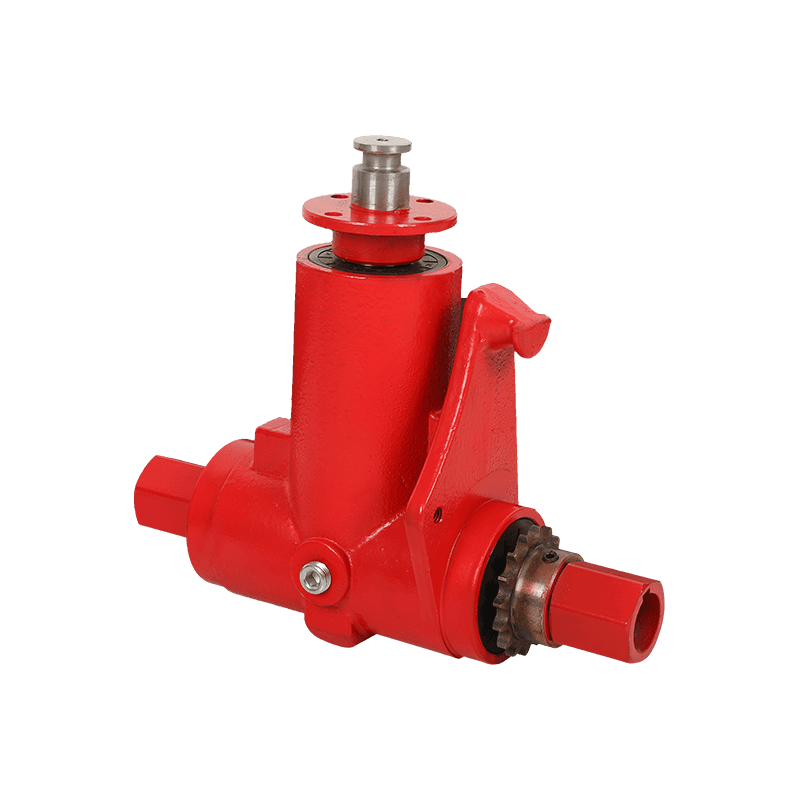

4. Agriculture

- Tractors and harvesters

- Irrigation systems

How to Select the Right Universal Gearbox

Choosing the correct gearbox ensures optimal performance and longevity. Consider the following factors:

1. Load Requirements

- Torque – Determine the required torque output.

- Speed – Assess input and output speed needs.

2. Environmental Conditions

- Temperature – Some gearboxes perform better in extreme heat or cold.

- Dust & Moisture – Sealed gearboxes are ideal for harsh environments.

3. Mounting Options

- Foot-mounted – For stable installations.

- Flange-mounted – For compact spaces.

4. Efficiency & Maintenance

- Gear Material – Steel gears last longer than plastic ones.

- Lubrication – Some gearboxes require frequent oil changes.

Advantages of Universal Gearboxes

- Cost-Effective – Reduces the need for multiple specialized gearboxes.

- Easy Integration – Compatible with various motors and machinery.

- Scalability – Can be modified for different power requirements.

Common Issues & Troubleshooting

Even the best gearboxes may encounter problems. Here are some common issues and solutions:

| Issue |

Possible Cause |

Solution |

| Overheating |

Excessive load or poor lubrication. |

Reduce load or check oil levels. |

| Noise/Vibration |

Misalignment or worn gears. |

Realign gears or replace damaged parts. |

| Leakage |

Damaged seals or gaskets. |

Replace seals and inspect housing. |

Future Trends in Gearbox Technology

With advancements in engineering, universal gearboxes are evolving to meet modern demands:

- Smart Gearboxes – IoT-enabled sensors for predictive maintenance.

- Lightweight Materials – Carbon fiber and composites for better efficiency.

- Higher Precision – Improved manufacturing techniques for smoother operation.

Conclusion

Universal gearboxes are indispensable in modern machinery, offering flexibility, durability, and efficiency. By understanding their types, applications, and selection criteria, professionals can make informed decisions that enhance system performance. Whether used in industrial, automotive, or renewable energy sectors, the right gearbox ensures seamless power transmission and long-term reliability.

English

English 中文简体

中文简体 عربى

عربى русский

русский Español

Español