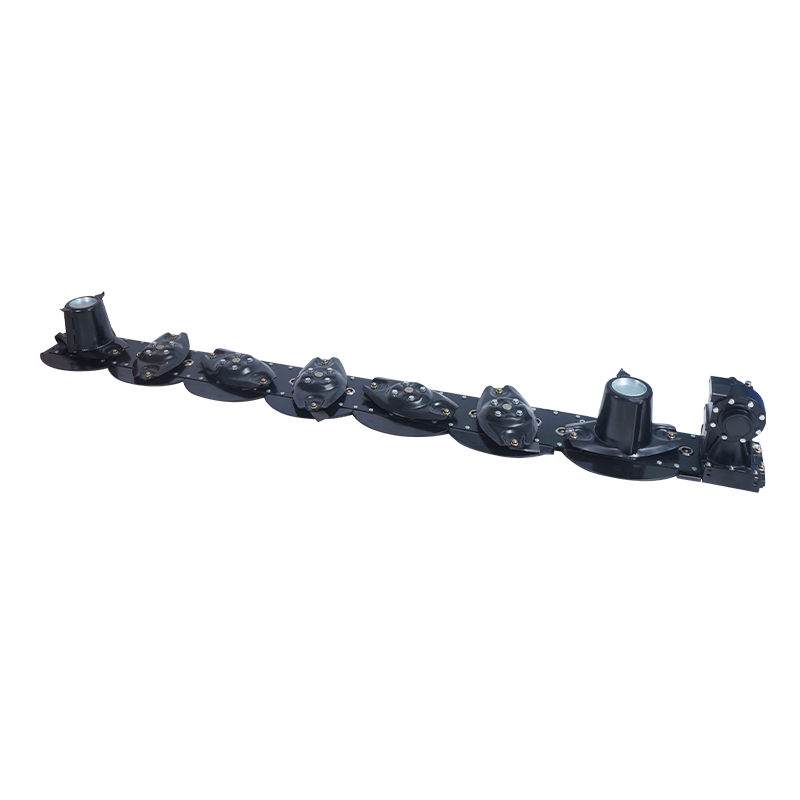

In the world of modern agriculture, where precision dictates productivity and efficiency underpins profitability, the fertilizer spreader gearbox plays a pivotal, though often underappreciated, role. It is not merely a mechanical component—it is the nerve center of an entire distribution system, responsible for synchronizing the movement of gears, paddles, and spinners that broadcast nutrients with surgical precision.

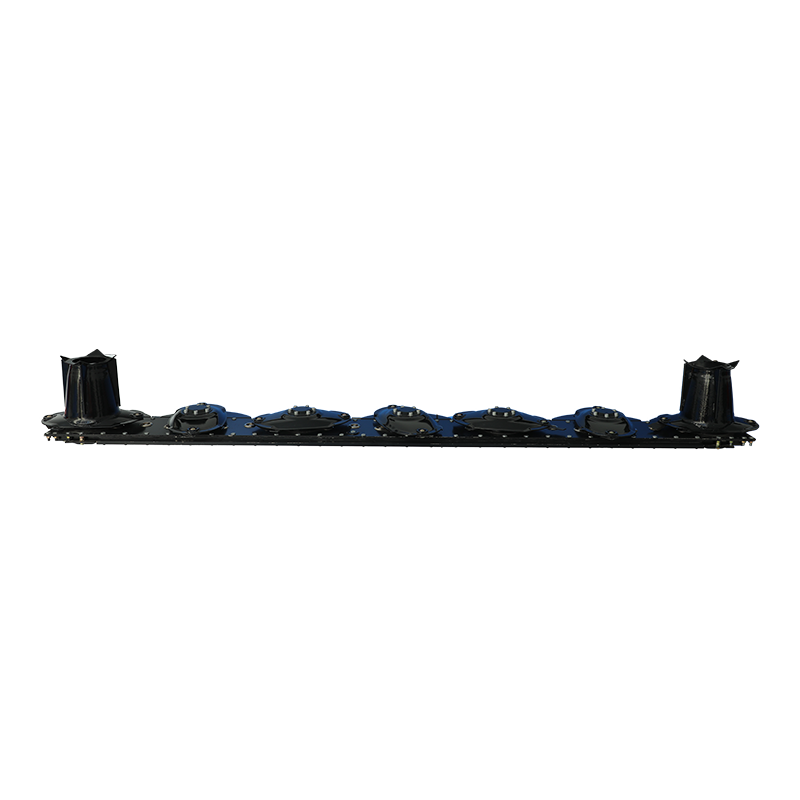

A fertilizer spreader gearbox, at its core, translates engine power into regulated motion. Yet, this deceptively simple function demands a level of engineering rigor and operational reliability that belies its modest size. The gearbox must endure the relentless stresses of outdoor operation—vibration, moisture, corrosive chemicals, and temperature extremes—without faltering or failing. Every rotation, every torque adjustment, every calibrated gear ratio ensures that the exact amount of fertilizer is dispersed across sprawling fields, evenly and efficiently.

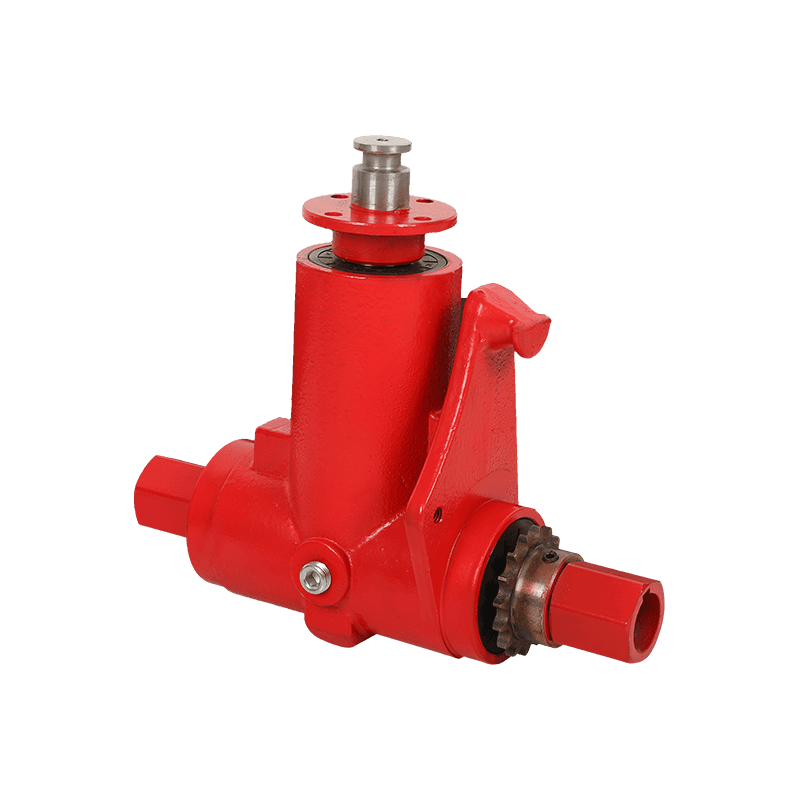

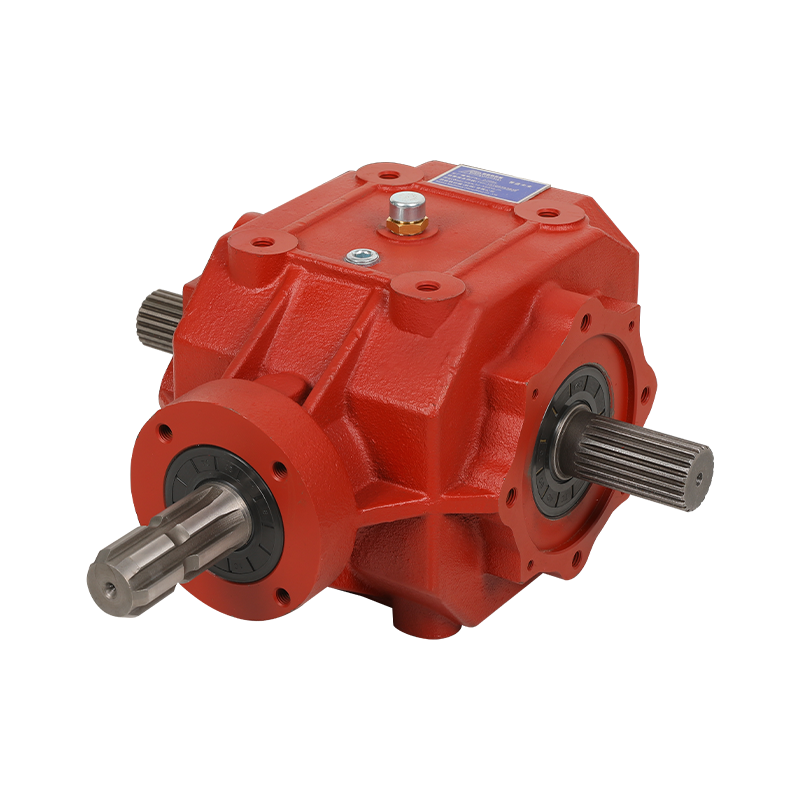

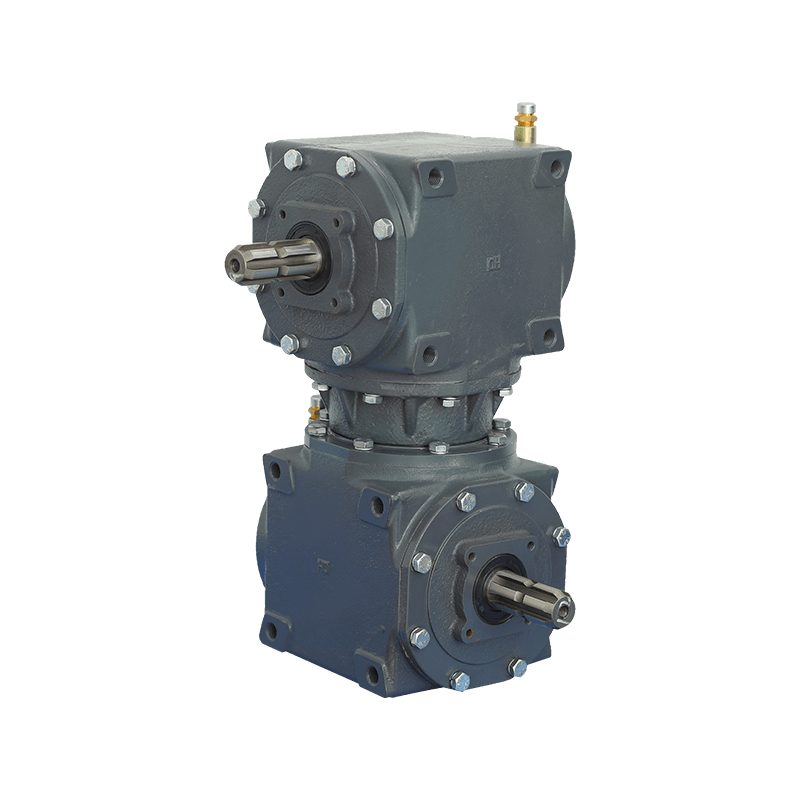

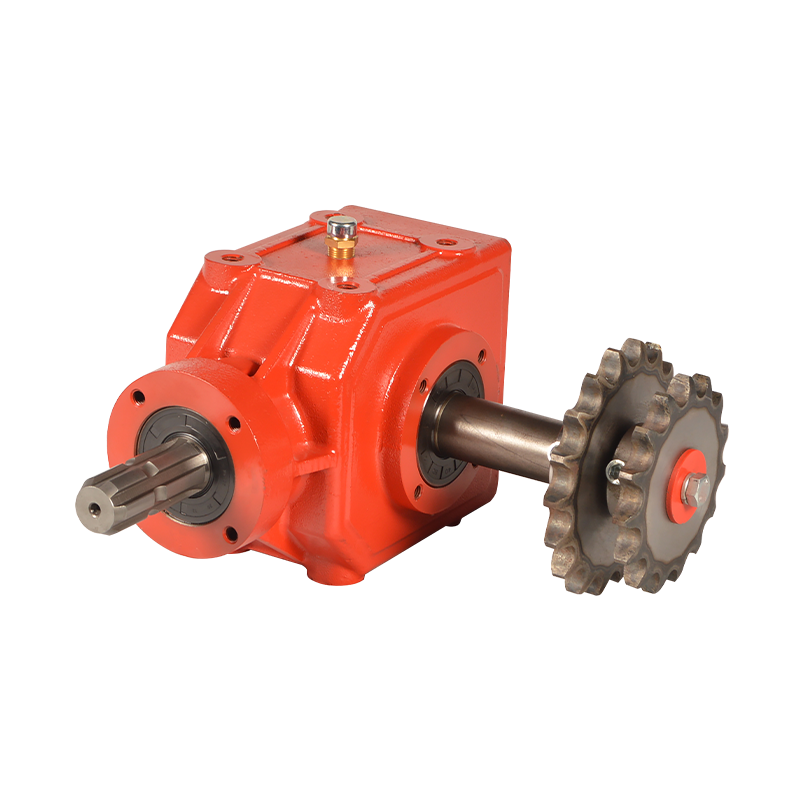

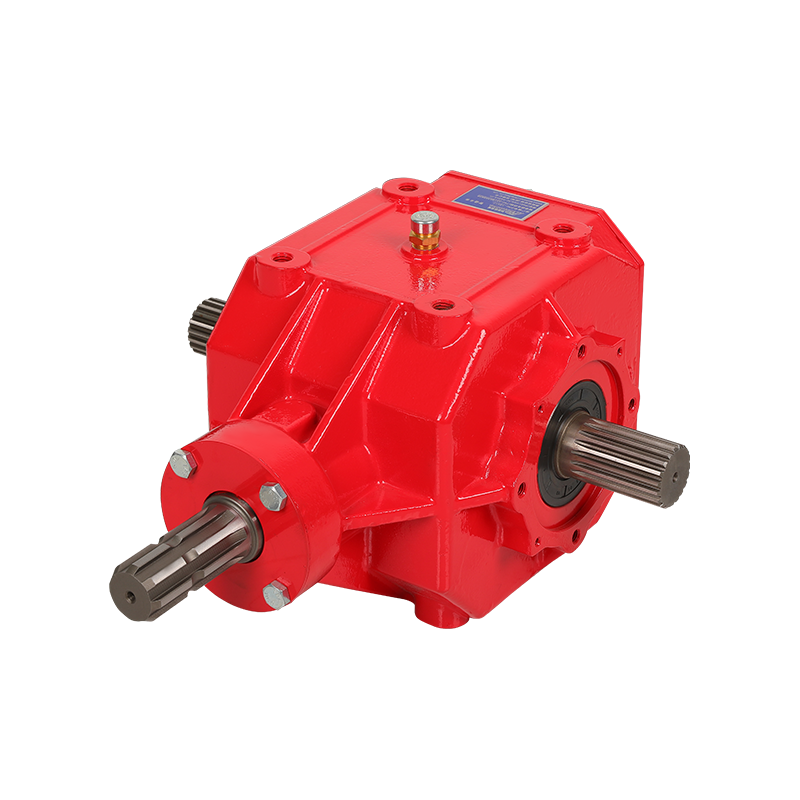

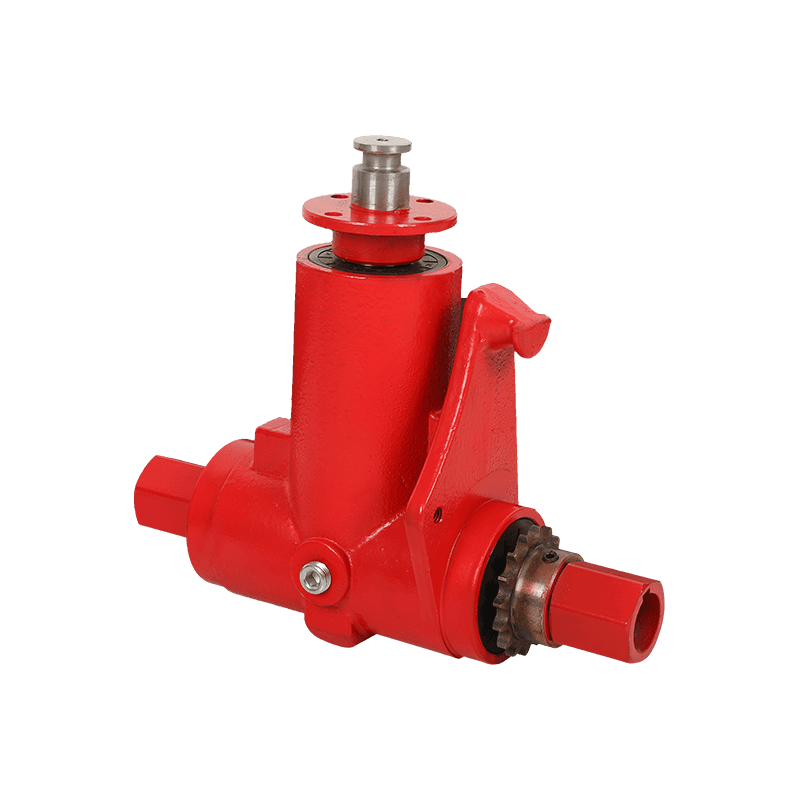

What distinguishes a high-performance fertilizer spreader gearbox is its marriage of durability and finesse. Hardened steel gears, sealed housings, and advanced lubrication systems are standard fare. But true excellence lies in design versatility—the ability to integrate seamlessly with various drive systems, from PTO shafts to hydraulic motors. Farmers require flexibility. Crops vary. Soil types differ. Equipment configurations shift with each season. A robust gearbox adapts without compromise.

Modern gearboxes incorporate features once considered luxuries: multi-speed adjustments, overload protection, and quick-change gear modules. These are not ornamental enhancements—they are necessities born from the demands of scale farming and precision agriculture. When working across thousands of acres, a single distribution error can result in nutrient waste, uneven growth, or costly reapplications. The gearbox must not merely function; it must excel.

Furthermore, efficiency is no longer optional. With input costs rising and sustainability becoming a critical benchmark, gearboxes must be engineered to maximize energy transfer and minimize mechanical losses. Smooth gear meshing, optimized tooth profiles, and reduced friction surfaces are the invisible guardians of fuel efficiency and machine longevity.

But performance is only part of the equation. Maintenance—or the lack thereof—has become a deciding factor in gearbox selection. Farmers cannot afford downtime. Gearboxes today must offer tool-free access for inspection, extended service intervals, and diagnostic indicators for early fault detection. Some advanced models are even equipped with smart sensors, integrating with GPS-based systems to regulate spreading rates in real time, responding dynamically to field conditions and application maps.

This evolution isn’t theoretical. It is already happening. Equipment manufacturers and gearbox specialists are collaborating to create bespoke solutions for every category—from compact broadcast spreaders used in orchards to massive self-propelled units operating across industrial-scale farms. The demand is clear: stronger, smarter, simpler.

In an era where every seed is counted and every granule matters, the fertilizer spreader gearbox is no longer a silent partner. It is a critical agent of precision, enabling agribusinesses to meet the twin imperatives of yield and stewardship. It allows operators to do more with less—to fertilize not just expansively, but intelligently.

The gearbox is not just a conduit of power. It is a curator of consistency. A sentinel of soil health. A quiet enabler of agricultural progress. Choosing the right fertilizer spreader gearbox isn’t just about machinery—it’s about aligning mechanical integrity with agronomic intent.

When performance meets precision, and endurance meets adaptability, the result is not just better equipment—it’s a smarter harvest.

English

English 中文简体

中文简体 عربى

عربى русский

русский Español

Español