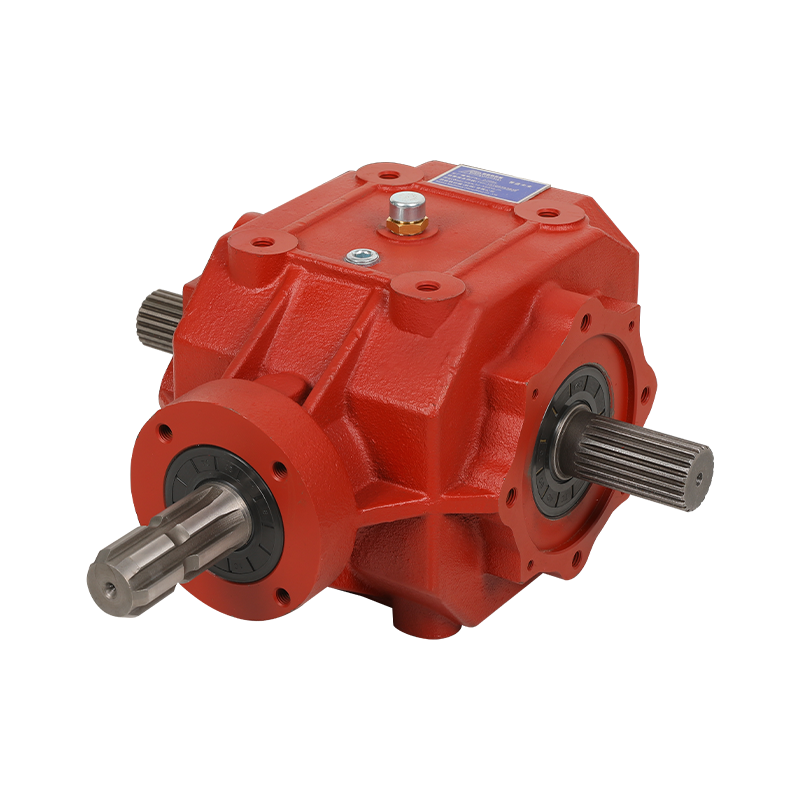

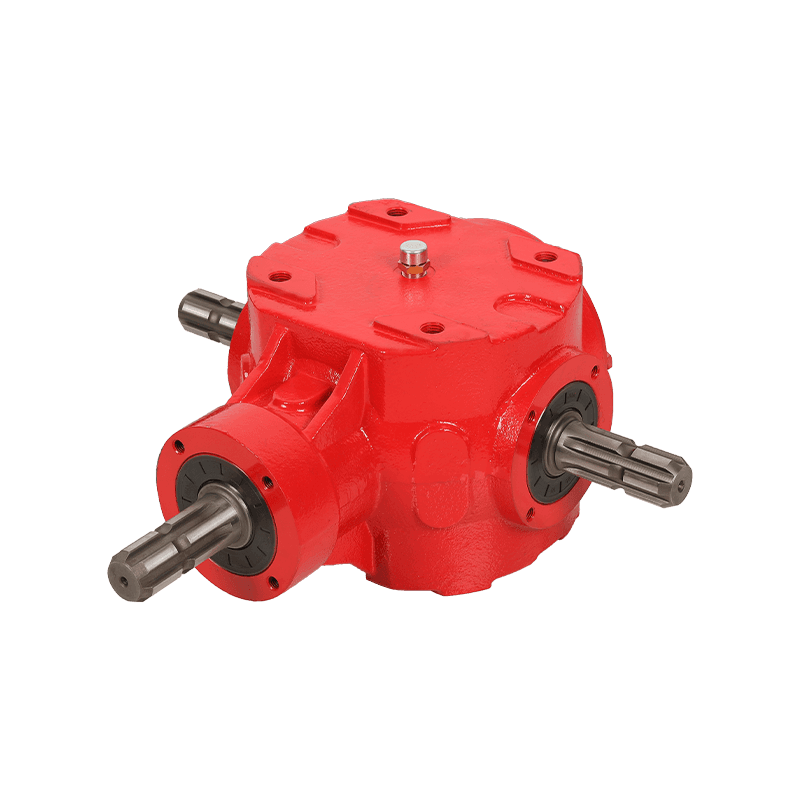

Universal gearbox are essential components in many industrial and mechanical systems. They transmit power, adjust torque, and control speed between machinery. Whether you're an engineer, mechanic, or hobbyist, understanding universal gearboxes can help you optimize performance and efficiency in your projects.

What Is a Universal Gearbox?

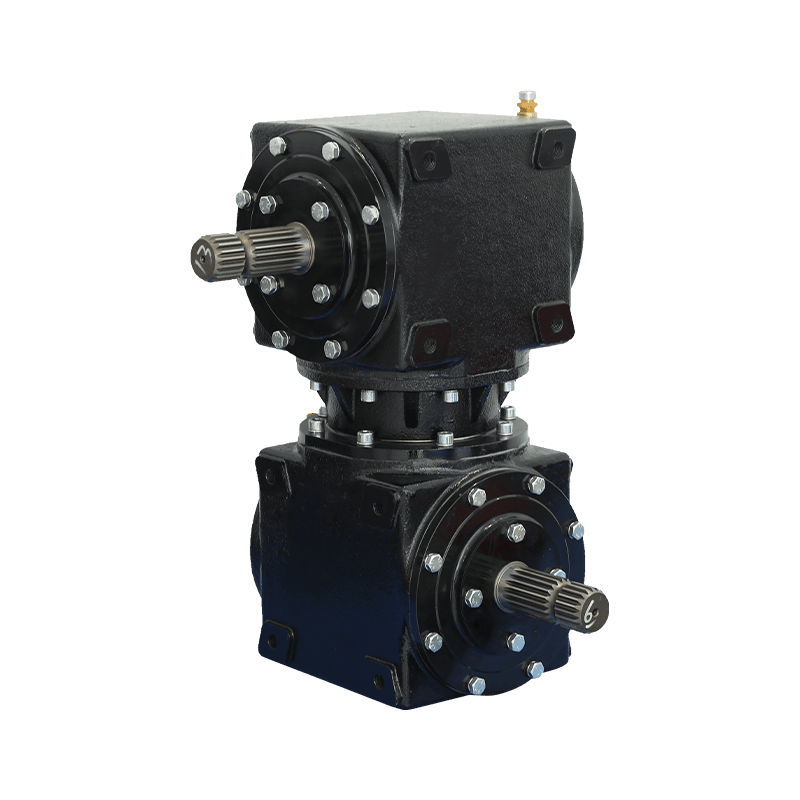

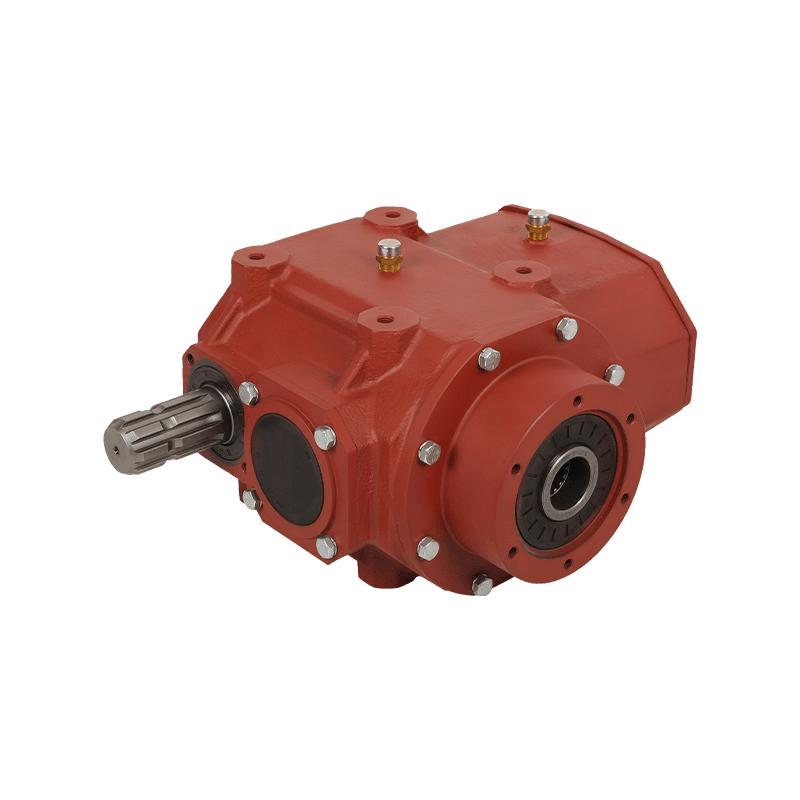

A universal gearbox is a mechanical device that transfers power from one part of a machine to another while modifying speed and torque. It consists of gears, shafts, bearings, and a housing that ensures smooth operation. These gearboxes are widely used in industries such as manufacturing, automotive, agriculture, and robotics.

Key Benefits of Universal Gearboxes

- Versatility: Compatible with various machinery and applications.

- Efficiency: Reduces energy loss by optimizing torque and speed.

- Durability: Built to withstand heavy loads and harsh conditions.

- Customization: Available in different sizes and gear ratios.

Types of Universal Gearboxes

There are several types of universal gearboxes, each suited for specific applications. Below is a comparison table:

| Type |

Description |

Best Applications |

| Helical Gearbox |

Uses angled gears for smooth, quiet operation. |

Conveyors, mixers, industrial machinery. |

| Worm Gearbox |

Provides high torque with a compact design. |

Lifts, elevators, heavy-duty machinery. |

| Planetary Gearbox |

Offers high efficiency and load distribution. |

Robotics, aerospace, precision equipment. |

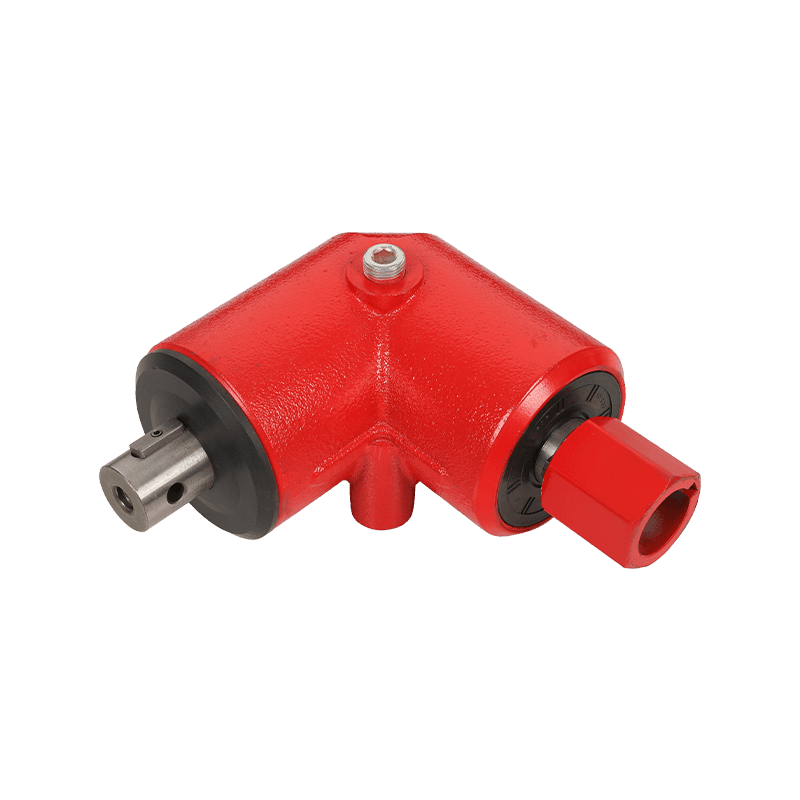

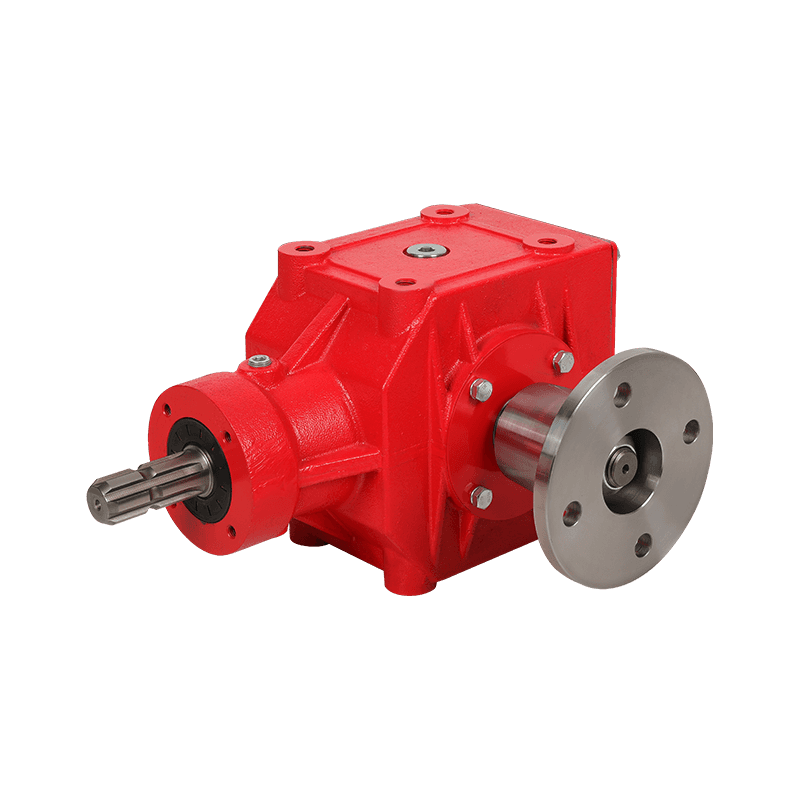

| Bevel Gearbox |

Transmits power at right angles. |

Automotive differentials, printing presses. |

How to Select the Right Universal Gearbox

Choosing the correct gearbox depends on several factors:

- Load Requirements: Determine torque and speed needs.

- Environment: Consider temperature, dust, and moisture exposure.

- Mounting Style: Ensure compatibility with your machinery.

- Efficiency: Look for energy-saving designs if operating costs are a concern.

Common Applications of Universal Gearboxes

Universal gearboxes are used in a wide range of industries:

- Manufacturing: Conveyor belts, assembly lines.

- Agriculture: Tractors, harvesters, irrigation systems.

- Automotive: Transmissions, power steering systems.

- Renewable Energy: Wind turbines, solar tracking systems.

Maintenance Tips for Universal Gearboxes

Proper maintenance extends the lifespan of your gearbox:

- Regular Lubrication: Use the recommended oil or grease.

- Inspect for Wear: Check gears and bearings periodically.

- Monitor Noise and Vibration: Unusual sounds may indicate issues.

- Keep It Clean: Prevent dust and debris buildup.

Signs Your Gearbox Needs Replacement

Watch for these symptoms of a failing gearbox:

- Excessive noise or grinding sounds.

- Oil leaks or overheating.

- Decreased performance or power loss.

- Visible damage to gears or housing.

Universal Gearbox Buying Guide

Follow these steps when purchasing a gearbox:

- Calculate torque and speed requirements.

- Choose the appropriate gear ratio.

- Verify mounting and shaft compatibility.

- Compare efficiency ratings.

- Check warranty and support options.

Frequently Asked Questions (FAQs)

Q: Can a universal gearbox be repaired instead of replaced?

A: Yes, if the damage is minor, repairs like bearing replacement or resealing may suffice.

Q: How often should gearbox oil be changed?

A: Typically every 2,000 to 5,000 operating hours, but check the manufacturer's guidelines.

Q: What is the average lifespan of a universal gearbox?

A: With proper maintenance, a gearbox can last 10-20 years, depending on usage.

Conclusion

Universal gearboxes play a crucial role in many mechanical systems. Understanding their types, applications, and maintenance can help you make informed decisions, whether you're selecting a new gearbox or maintaining an existing one. By following the guidelines in this article, you can ensure optimal performance and longevity for your equipment.

English

English 中文简体

中文简体 عربى

عربى русский

русский Español

Español