In the complex theater of industrial machinery, precision, adaptability, and reliability are non-negotiable. At the center of this mechanical ballet is a component often overlooked but undeniably vital — the universal gearbox. Engineered to bridge disparate systems and synchronize dynamic motion, the universal gearbox is more than just a mechanical intermediary. It’s the linchpin of seamless power transmission across diverse industrial applications.

The Engineered Elegance of a Universal Gearbox

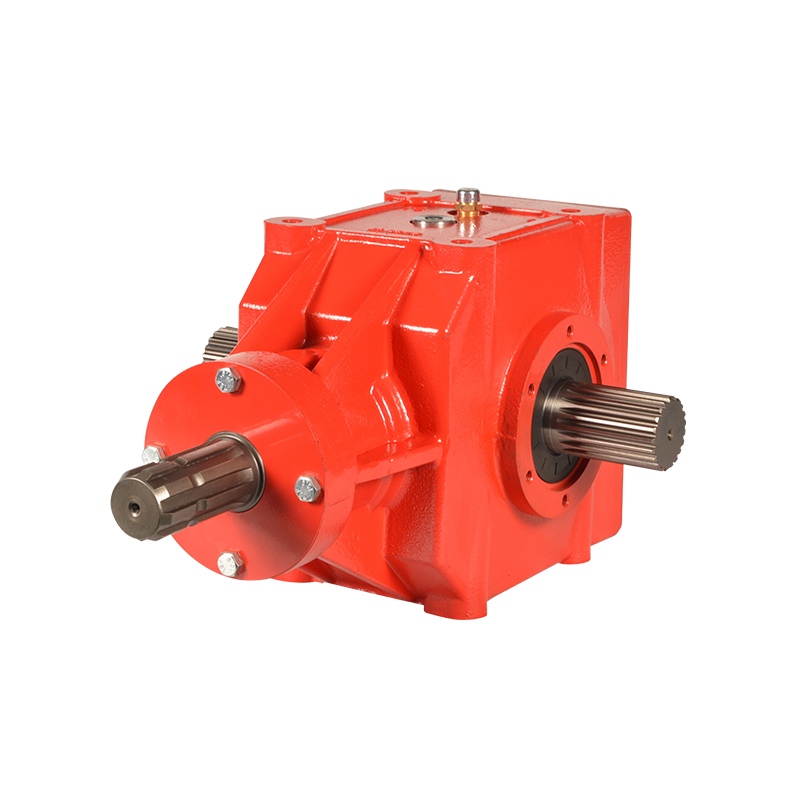

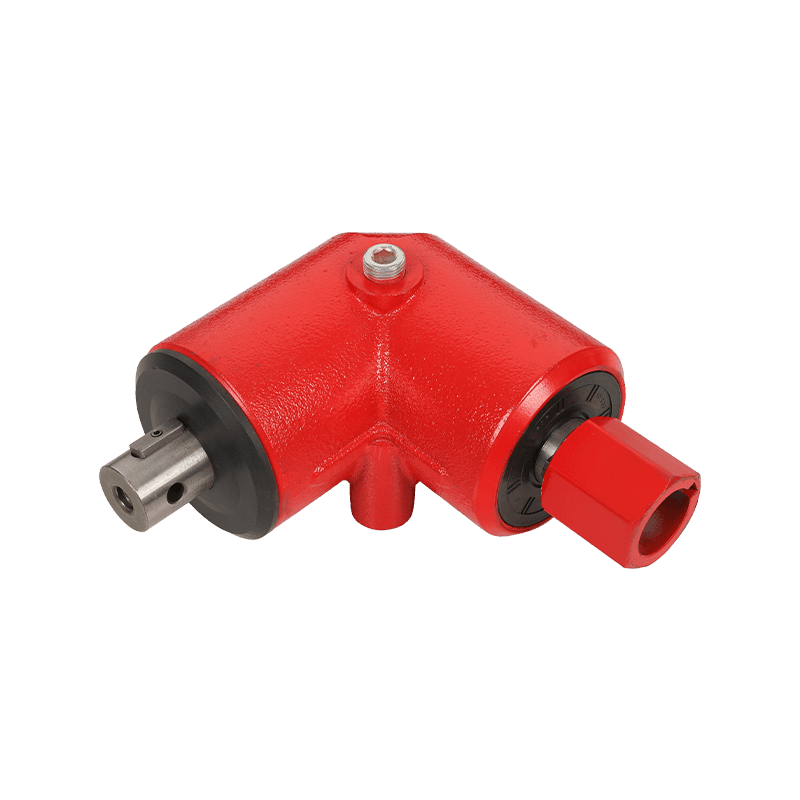

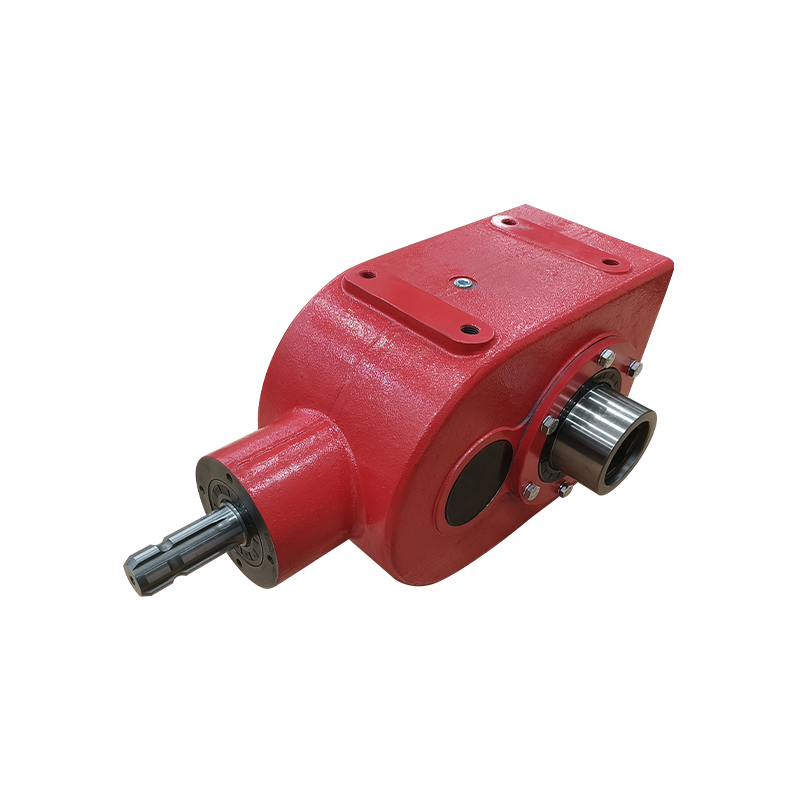

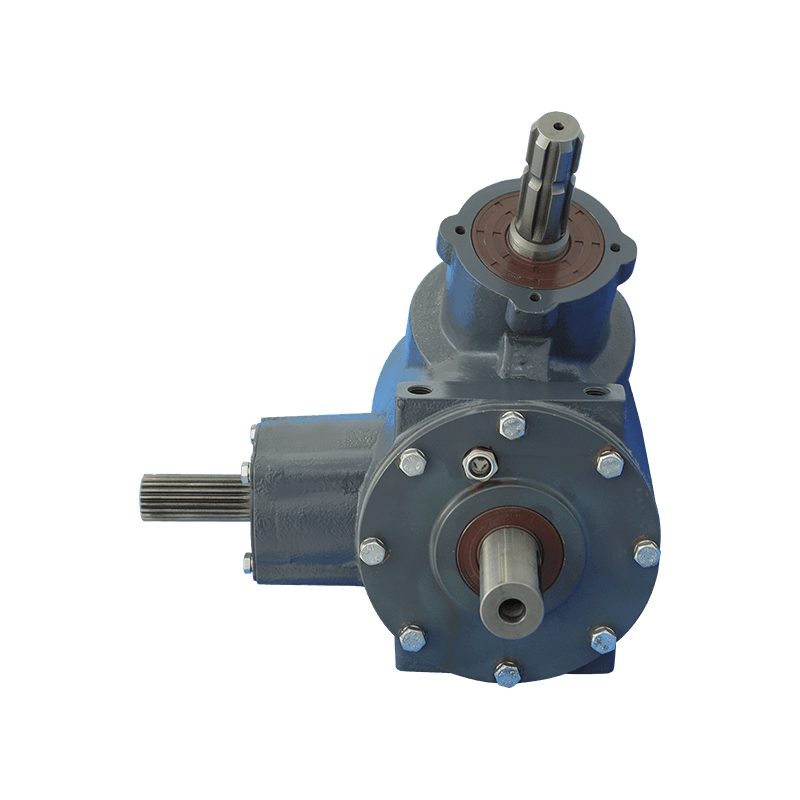

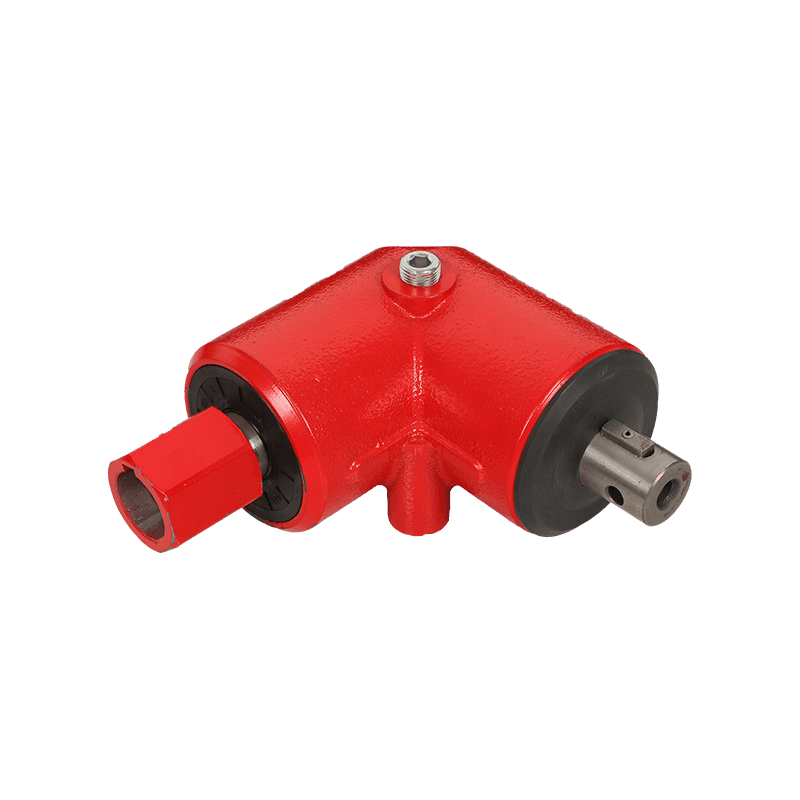

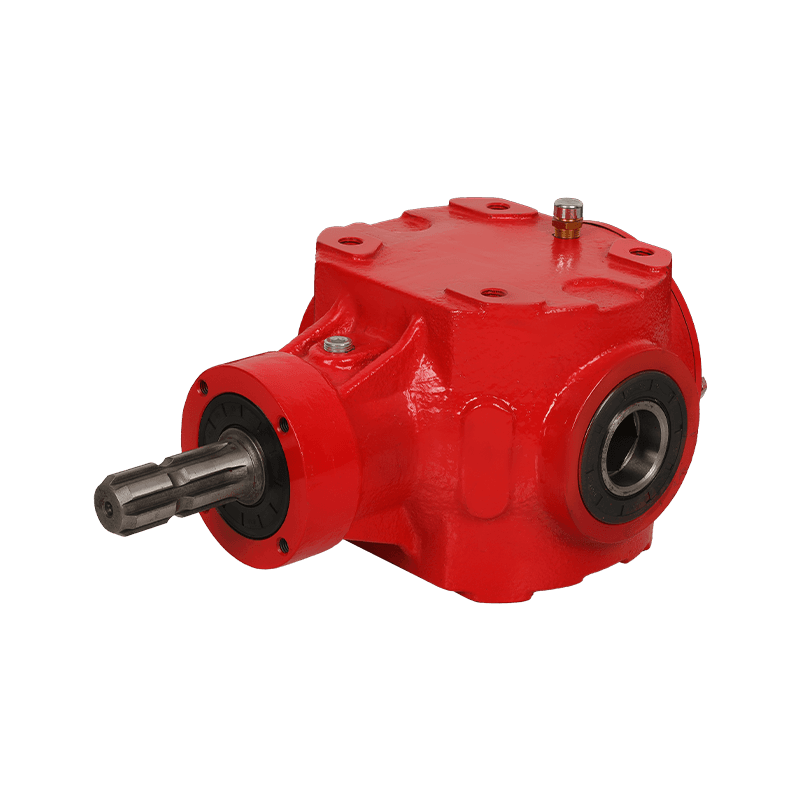

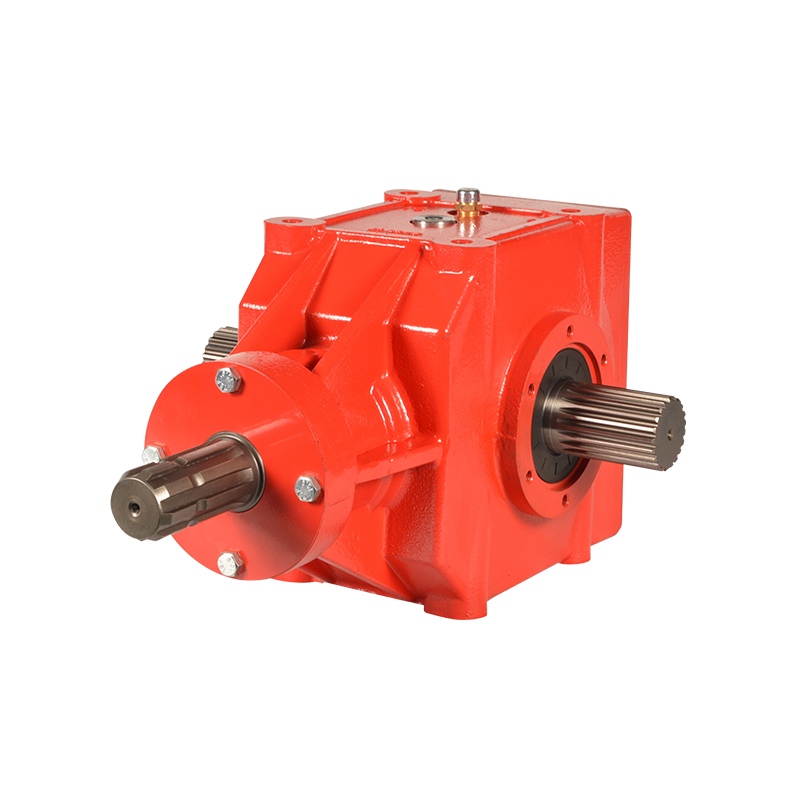

At its core, a universal gearbox is a modular transmission unit designed to accommodate multiple configurations and torque demands. Unlike traditional gearboxes limited by design specificity, the universal variant embodies flexibility. It’s a chameleon — adapting to mounting orientations, input-output configurations, and speed-torque ratios with minimal modification.

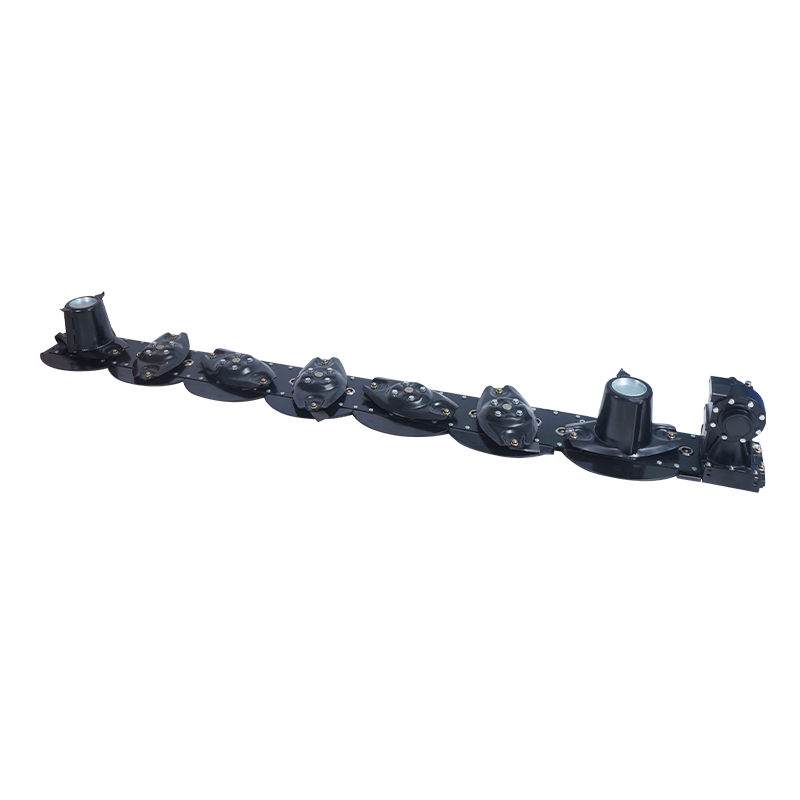

This type of gearbox is meticulously crafted to serve both high-performance precision tasks and heavy-duty operations. Whether nestled in the guts of a conveyor system or driving the rotational heart of a wind turbine, it maintains consistent output with minimal backlash and optimal efficiency.

Built for Adaptability

A standout feature of the universal gearbox is its architectural modularity. This design philosophy allows users to customize gear ratios, shaft arrangements, and housing structures without re-engineering the entire system. In essence, it eliminates the costly, time-consuming necessity for bespoke solutions.

From right-angle to inline orientations, from worm drives to helical gears — the universal gearbox can morph and perform. This adaptability translates into an extraordinary breadth of applications, spanning industries such as aerospace, mining, automotive, packaging, renewable energy, and beyond.

Torque That Speaks Volumes

Power means little without control. The universal gearbox offers both. Engineered with premium-grade alloys and precision-milled gearsets, these systems deliver high torque output with impressive stability. Advanced lubrication channels and thermal management features ensure endurance even in punishing environments.

Low noise. Minimal vibration. Remarkable thermal tolerance. The universal gearbox doesn’t just transmit force — it refines it. Such qualities are indispensable in modern manufacturing, where downtime equates to lost revenue and compromised reputation.

Operational Excellence Across Environments

Whether operating in cryogenic conditions or under relentless heat, the universal gearbox retains its composure. Protective coatings, sealed bearings, and high-performance seals ensure it remains impervious to dust, moisture, and chemical intrusion. For offshore rigs, desert rigs, or cleanroom facilities, this gearbox stands ready.

Maintenance-friendly design is another unsung virtue. Easy-access inspection ports, modular subcomponents, and standardized parts streamline serviceability. In sectors where operational continuity is mission-critical, this becomes a substantial competitive advantage.

The Sustainability Equation

Today’s industrial landscape demands more than brute strength — it demands conscience. Universal gearboxes answer the call with energy-efficient performance that reduces waste and cuts power consumption. Optimized gearing geometries minimize friction losses, while sealed-for-life lubrication systems eliminate environmental contamination risks.

By extending operational lifespan and reducing maintenance frequency, universal gearboxes align with green manufacturing initiatives and sustainable engineering standards — a pivotal consideration in ESG-focused operations.

The universal gearbox isn’t merely a component; it’s a catalyst. It enables machinery to function with grace under pressure, empowers systems to evolve without constraint, and ensures that industries — from agriculture to aerospace — run without interruption.

In a world increasingly driven by automation, modularity, and sustainable performance, the universal gearbox holds its place not in the spotlight, but in the heart of the system — quiet, unassuming, and indispensable.

English

English 中文简体

中文简体 عربى

عربى русский

русский Español

Español