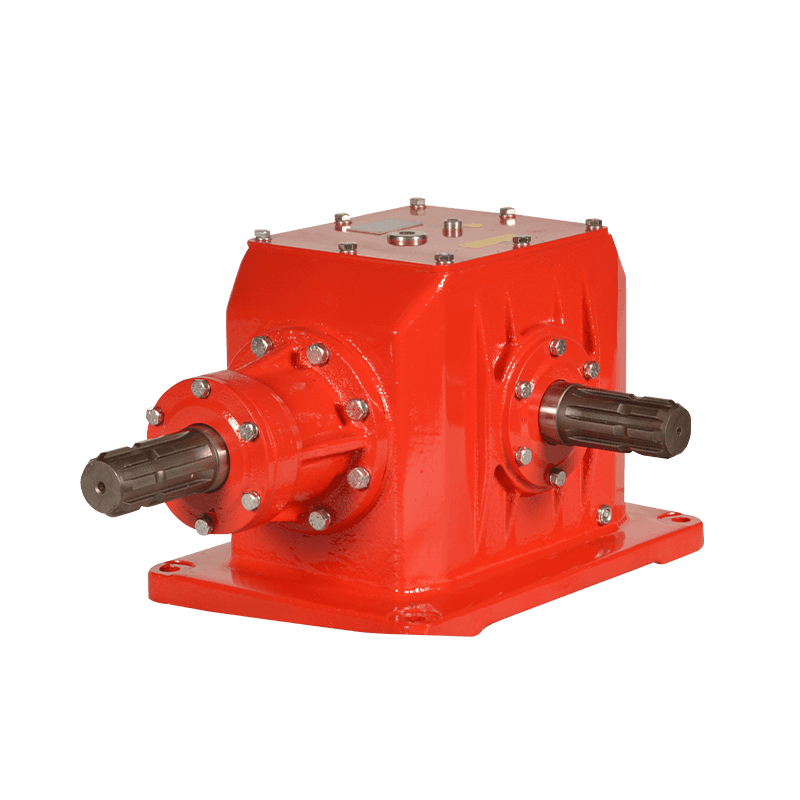

KLF100 Light-weighted crawler tractor gearbox

Cat:Grader Driven Rake Gear Box

This gearbox is used for lightweight crawler Tractors within 80HP. Engine input, power, and torque are transmitted through the gearbox. By driving the...

See DetailsIn the intricate world of agricultural machinery, where efficiency dictates productivity and downtime is a costly adversary, the square baler type gear box emerges as a vital cog in the baling process. It is not merely a mechanical component—it is the strategic heartbeat of baling operations, designed to deliver consistent torque, robust durability, and impeccable synchronization.

At its core, a square baler type gear box is engineered to withstand the punishing demands of compressing and shaping hay, straw, or silage into uniform square bales. Unlike round balers that require a different dynamic approach, square balers operate in a rhythmic, linear fashion. This requires a gearbox capable of managing high loads with surgical precision, without compromising on speed or structural integrity.

The gearbox’s primary function is to translate the rotational power from the tractor’s PTO (power take-off) into the mechanical motion necessary to drive the plunger, knotters, and pickup assembly. This orchestration must be impeccably timed. Any deviation or delay can result in missed ties, fragmented bales, or complete system failure. Precision, therefore, is non-negotiable.

What sets a square baler gearbox apart is its rugged construction. Housed in corrosion-resistant, high-tensile cast iron or aluminum alloys, the unit resists wear even under prolonged exposure to dust, moisture, and fluctuating temperatures. Internally, heat-treated steel gears operate in harmony—spiral bevels, helical gears, and planetary systems are common within more advanced models. Lubrication channels are meticulously routed to ensure optimal viscosity retention and thermal dissipation.

Adaptability is another hallmark. Gearboxes can be configured for various torque outputs and gear ratios, allowing them to be seamlessly integrated into small-scale balers or high-output industrial units. Many are designed with modularity in mind, simplifying maintenance and enabling swift replacement of critical components without extensive teardown.

Yet, the importance of a high-quality gearbox transcends the hardware. Its design directly impacts fuel efficiency, operational noise, and bale density. A gearbox that minimizes friction and operates with minimal vibration reduces the mechanical strain on both the baler and the tractor. The result? Lower fuel consumption, quieter operation, and denser, cleaner bales that stack with military precision.

Manufacturers are increasingly incorporating smart diagnostics and condition monitoring into their gearboxes. Sensors relay real-time data on temperature, vibration, and gear wear, empowering operators with predictive maintenance insights. This evolution from passive machinery to intelligent systems is reshaping the agricultural equipment landscape.

The square baler type gearbox is more than a drive system—it's a linchpin of productivity. Its role is foundational, yet often underappreciated, in the broader pursuit of efficient crop management. When engineered with foresight and precision, it enables balers to perform flawlessly across countless acres, turning raw material into a uniform commodity ready for storage, transport, or sale.